Other Willcox and Gibbs Sewing Machines

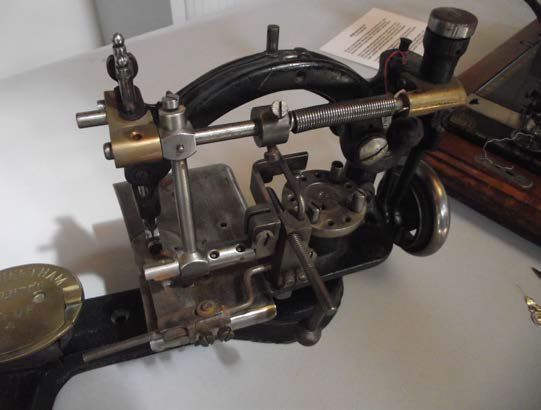

Fig. 1: The basic W&G manufacturing machine

Fig. 3: Close-up of the straw braid guides

W&G’s first machine was the small chainstitch machine which is present in most of our collections. However, they made many other types of machine, several of which were market leaders in their day. Most of these were aimed at the light industrial market and several had production lives of over half a century.

The small chainstitch machine itself was used as the frame of numerous specialised industrial machines.

The first version of ‘Automatic manufacturing machine’ had a more robust feed mechanism and a larger reel holder (Figure 1), otherwise it was the standard machine and was also available without the Automatic Tension. It was recommended for attaching fancy lace goods, linings for caps and shoes etc.

As time passed, more and more complex modifications were grafted onto the machine.

Straw hats were very popular in the nineteenth century with, at one time, an estimated 20 000 people in the Luton and Dunstable area supplemented their living from plaiting the straw braid from which they were made. Figures 2 & 3 show the W&G variant which was launched in 1875 as the ‘visible-stitch straw hat machine’.

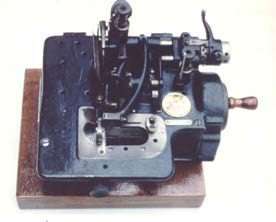

Another variant of the chainstitch machine for the hat-making industry was patented on 7th June 1898 by F. W. Cheetham (No. 12709) for sewing linings and trimmings onto the brims of hats (Figure 4). Both these machines were on display at the AGM.

Fig. 2: W&G chainstitch machine modified for sewing straw hats

Fig. 4: Cheetham’s version of the chainstitch machine for trimming hats

Some of the manufacturers who cloned the chainstitch machine also made small industrial versions of their clones, e.g. Heinrich Grossmann’s ‘Dresdensia’ straw hat machine.

In 1876 W&G bought the Wiseman patents for the ‘hand stitch straw hat machine’ and produced their own version usually known as the ‘box’ machine (Figure 5). This was said to use 20 to 25 per cent less thread than the ‘visible stitch’ machine as well as producing a firmer yet more elastic seam.

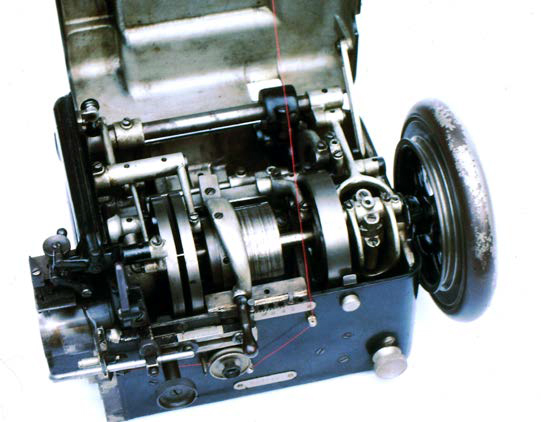

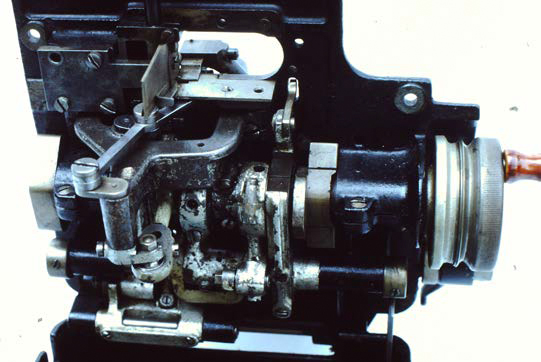

All the mechanism is enclosed in a cast iron box which makes a very neat machine but one difficult to dismantle and service (Figure 6). W&G continued to provide spares for these machines into the 1950s.

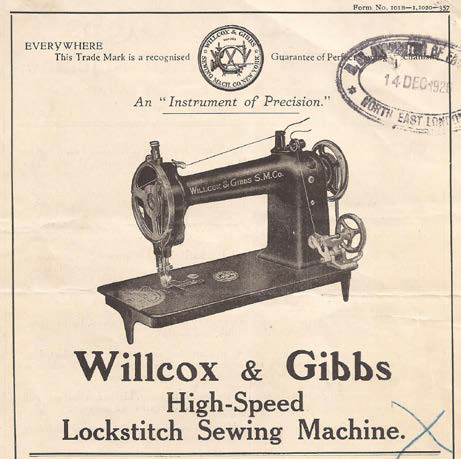

W&G also made lockstitch machines. Their ‘No. 10’ high speed lockstitch machine of the 1890s was a world beater. It featured a rotary thread take-up and an eyeleted-belt drive to the lower shaft which rotated at three times the speed of the upper shaft. It was claimed to make up to 4000 stitches per minute. At ten stitches per inch, that is over 6 inches of seam per second; an operator with skillful hands is needed.

Fig. 5: W&G ‘box’ or ‘hand stitch straw hat machine’

Fig. 6: The interior of the ‘box’ machine

Fig. 7: W&G ‘No. 10’ high speed lockstitch machine

Fig. 8 (above): Advertisement for the ‘No. 10’ machine

Fig. 9: W&G overlocker of c1900, the two thread version

Even Singer made a copy of it (Figures 7 & 8). Later versions had a pumped oil supply to the main bearings and would tackle a very large range of light industrial tasks. They were particularly popular with outworkers who rented the machines to work at home.

In the nineteenth century, sewing together and binding the edges of two pieces of cloth was known as ‘overseaming’. Amongst the first overseaming machines were those of the American B H O & Sewing Machine Co. of Philadelphia.

W&G introduced their overseamer incorporating a trimming knife to ensure an even bound seam, in 1889. They called their machine an ‘overlocker’ (registered as a W&G trademark) and now everyone calls such machines ‘overlockers’ (Figures 9 & 10). The machine was originally designed for the hosiery trade for joining and trimming knitted fabric in the underwear industry. Capable of 3000 stitches per minute it was advertised as ‘a hundred times faster than was possible in the case of overcast stitching by hand.’ Later versions could overedge, scallop and insert a cord in one operation. Like the ‘No. 10’ lockstitch machine these remained in commercial used for over 60 years.

Willcox & Gibbs were an innovative and major player in the American sewing machine industry for nearly a century. All the machines were very well engineered and top of their range.

by Martin Gregory

Fig. 10: The mechanism of the overlocker.