Mechanising the Factory

ONE OF THE problems which faced sweatshop owners when it came time to mechanising the factory was not what form of motive power to use - steam was the only answer - but how to deliver it.

Miles of overhead belting and shafting was noisy, unsafe, needed frequent greasing and, more important, did not provide an easy and quick way of regulating individual machines.

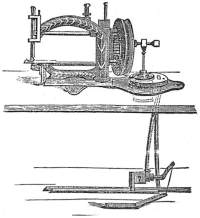

Messrs Mee & Balfour came up with an answer in 1875 with a patent which provided each machine with a miniature engine but driven from a central boiler which provided the steam via piping under the work bench.

Each machine operator had a pedal by which the amount of steam to the individual engine could be regulated

The simple engine used a connecting rod from the top of the piston to the drive wheel.

The inventors claimed that a machine could make from five to 5,000 stitches a minute if fitted with the device.

A gas-powered steam generator was also offered and it was said that an operator could work twice as fast with the "direct motor".

Running costs were said to be less than 4s per day for a factory with 50 machines.

Shortly after the invention was announced a company was formed, with a capital of 20,000, to market the device.

GF