From Eldredge to National to Janome:

Graham Forsdyke takes a brief look at the giant American company

National founder Barnabas Eldredge

by Graham Forsdyke

ISMACS News

Issue 55

April 1997

WITH THE vast majority of early sewing machine manufacturers based in the New England area, any company with a factory in the centre of the country has to be an exception.

We are talking about the National Sewing Machine Company here but the geography wasn't always so different.

Shortly after the Civil War, Barnabas Eldredge of Cleveland, Ohio, became interested in sewing machines and produced a model which had several improvement on the existing market leaders.

He looked around for a manufacturing plant and first followed tradition. In the mid-to-late 1800s most American precision engineering businesses were based on the East Coast and the Ames Manufacturing Company of Chicopee Falls in Massachusetts filled the bill. This was an arms and ammunition business well suited to the precision production of a quality sewing machine.

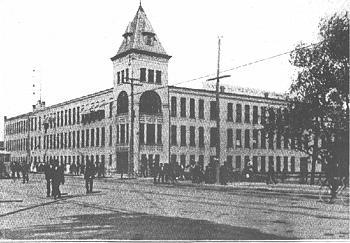

The National company headquarters as it was in 1906 when this postcard was sent from Belvidere Illinois to Northampton, Mass.

Things worked well initially but soon Eldredge realised that his best market was in the North West.

An agreement with Ames resulted in Barnabas buying the dies and other special tooling which were moved to Chicago where Eldredge engaged the June Manufacturing Company to continue production.

This time Eldredge chose a company that already had sewing- machine experience.

It was founded by F. T. June in 1879 and produced a Singer-clone machine under the name of Jennie June.

As part of the deal, the two companies co-existed for a time but with Eldredge becoming vice president of June.

Eldredge production boomed but the demand for June machines decreased and soon the entire factory was given over to making the Barnabas E-designed model. Only one problem faced the booming company -- the lack of a skilled workforce. Recruiting drives failed to fill the empty places and in 1886 the entire plant was loaded on specially-hired rail-freight wagons and transported to Belvidere Ill, a much smaller town but one with a wealth of engineering experience.

Only surviving picture of F. T. June, president of the June Company from 1879 to 1880

When F. T. June died in 1890, Eldredge consolidated the two businesses into the new National Sewing Machine Company.

He remained as president until his death in 1911. His successor was David Patton who had joined the company as an office boy 35 years before.

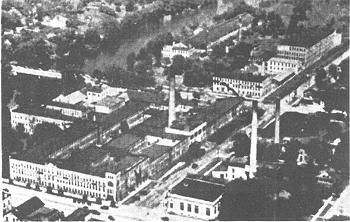

That first building in Belvidere was a small two story premises which was slowly expanded until, by the company's 60th anniversary, it covered over 20 acres -- and that was just floor space.

In 1900 a huge 500-foot-long foundry was built on the banks of the Kishwaukee River and in 1928 a new steam-driven generator was installed. It had the latest automatic stoking device and consumed over 40 tons of coal each day to light and power the factory.

There was no ageism at the National Company. Jobs for life were offered and in 1939 a company report showed that there were over 100 employees who were still working, although long past retirement age.

View of the factory as it was in 1939 presumably taken from an aeroplane

Perhaps one reason for the firm's longevity was its willingness to diversify. In the bicycle-boom years of the 1890s there was an Eldredge two-wheeler winning the prestigious six-hour race at Madison Square Garden in New York City.

And when the automobile came upon the scene in the first decade of the 20th century there was an Eldredge up there with the rest frightening the horses.

Washing machines, vices, food grinders all flooded out of the Belvidere factory.

And all the time the sewing-machine business went on.

Foundry workers in 1925

National was early into the badge machine business. Large department stores and mail order houses liked to sell goods with a name exclusive to their own business. National obliged by badging the machines with whatever name was needed -- if the order was big enough.

Macy in New York, Wannamaker in Philadelphia, Marshall Field in Chicago -- all were National customers. Macy bought its first National machines in 1897 and Montgomery Ward was a customer back in 1889 with the original Eldredge business.

A few important dates.

Workers in the National toolroom. This picture is from 1927

In 1910, National introduced the rotary Model A with automatic tension. This machine sold extremely well, customers attracted by its ability to adjust to thread and material thickness without manual adjustment.

National claims the first electric machine, developed for Western Electric in 1917 and later re-named the Greybar. There are other, better, claims to this title.

The Vindec C with capped needle bar and presser-foot bar to prevent dust entering the machine and promoting bearing wear was introduced in 1912, but perhaps the biggest step forward was the 1935 Reversew -- a long-shuttle machine which sewed in both directions.

Building the new foundry. Work started in 1900 and finished a year later.

To answer the Singer Featherweight, National produced its own aluminium portable in 1939 but it was never the success of the 221 and later 222 models from the Singer factory.

Somehow National never came together after the war. The company soldiered on until 1953 but then the influx of Japanese models became too much.