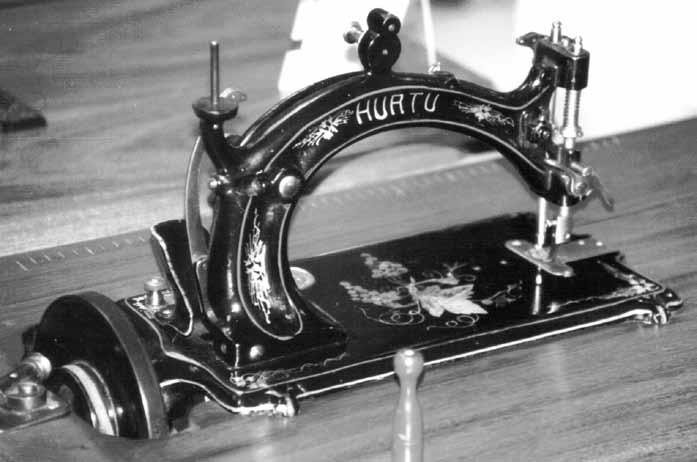

Hurtu Sewing Machines

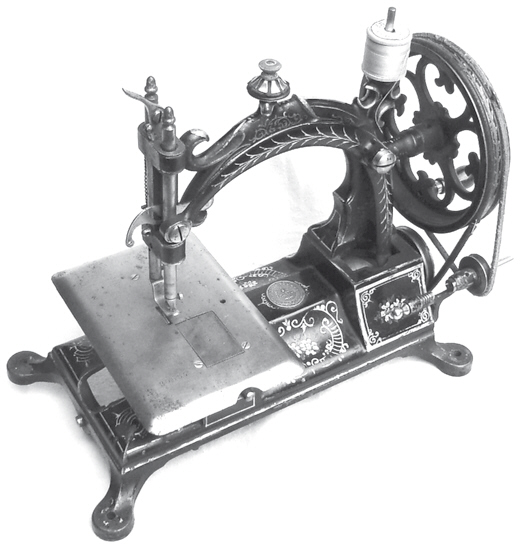

Fig 2: 'L'Abeille' hand machine

One of the best known French manufacturers of sewing machines was that of Hurtu. Auguste Jacques Hurtu made his first sewing machine, to sew leather, in 1861 in a small workshop in Paris.

Two years later he had a partner and the company became Hurtu and Stevens. By 1867 his partner was Victor Hautin and the company traded as Hurtu and Hautin.

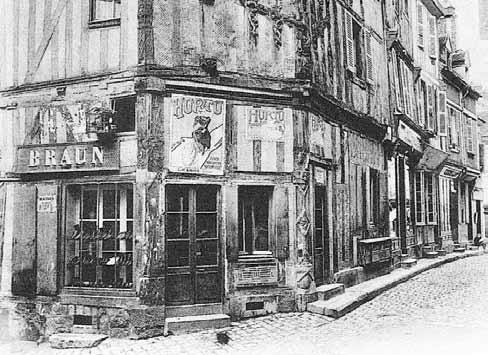

Both Hurtu and Hautin had been apprentices together in the workshops of De Wendel, maintaining locomotives. They had their office and 'steam powered' factory at 54 Rue St. Maur in the Popincourt suburb of Paris. There was a sales showroom at 33 Boulevard Sébastopol, a very fashionable Paris address.

Fig. 4: the brass medallion fixed to most Hurtu machines

They were keen to patent their improvements to sewing machines, both in France and, for their more important patents, in Belgium, England and America. In the 1860s, the largest user of sewing machines was Napoleon III's army and the Franco-Prussian war of 1871 provided the impetus and know-how for Hurtu and Hautin to use interchangeable manufacturing techniques and boost output to supply workshops and clothiers. By the early 1870s they were producing a range of machines for both family and commercial use. There were three domestic machines: 'La Merveilleuse' (The Wondrous One) which was a single thread chain stitch machine at 50 francs; 'La Productive' (The Productive one), a small boat shuttle hand machine at 90 francs; and 'L'Abeille' (The Bee), a slightly larger boat shuttle hand machine at 135 francs. 50 francs bought you a standard treadle stand and they also catalogued an ornate treadle for the 'Machine de Salon'. I have never seen 'La Merveilleuse' but 'La Productive' was available heavily pearled and 'L'Abeille', with more ornate castings, was described as 'speedy, noiseless, of elegant design' and 'infinitely superior to all that had gone before'.

Fig. 3: 'L'Abeille' machine & fancy single pillar stand

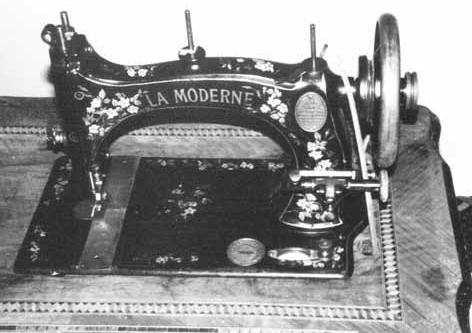

Fig. 12: 'La Moderne' VS machine of the 1890s

The commercial machines established the classic Hurtu open-framed machine which was available as both a flat-bed and a free-arm machine. The machines were available with different lengths of arm from 200 mm up to 500 mm. All were fitted with top feed operated by a large brass face cam behind the needle bar; a layout used by several French manufacturers at the time. They were mounted on treadle bases with two individual foot pedals phased 180o apart. This was also a characteristic layout used by many French makers. By 1876 production had risen to 5000 machines per year (a year in which Singer produced over 260 000 machines).

Fig. 11: 1890s VS domestic machine head

In 1874, a wealthy manufacturer in Rhode Island, America, called Joseph Banigan, visited Paris and bought the American rights to the Hurtu machines. A stock company was formed to manufacture the machines in Woonsocket RI, known as the Hautin Sewing Machine Co. Banigan soon claimed that the Hurtu designs, whilst probably sufficient for the 'slow-going people of France', were not competitive in the American market; hardly surprising when one realises that the Singer 12, 'New Family', had been around for several years and others like Domestic were making high arm totally enclosed models. A sewing machine engineer, Simon Wardwell, was called in to make improvements. Although Wardwell tinkered with the designs for four years, he failed to come up with a competitive machine and the project came to nought. Wardwell's own American sewing machine design, a two reel machine with a rotating head, was also a commercial flop!

Fig. 5: The classic open frame Hurtu free-arm machine on its treadle with two separate foot pedals. A wooden table is fixed round the free-arm for use as a flat-bed machine.

Through the 1880s, the company continued to innovate and, by 1910, had amassed over 70 patents. The three early domestic machines were phased out and replaced with an iron base, vibrating shuttle hand machine (designated No. 11) and both rotary hook and vibrating shuttle treadle machines were introduced. Despite the introduction of new models, total production did not rise as fast as the European sales of sewing machines.

Fig. 7: Detail of the classic Hurtu machine showing the rectangular section needle bar and large brass disc cam for top feed mechanism

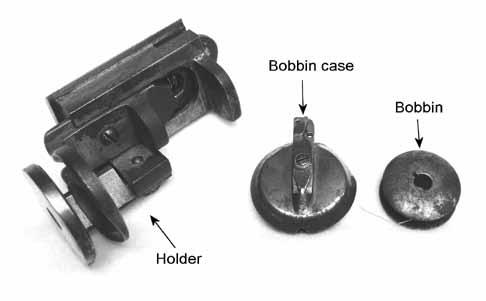

Fig. 9: The rotary hook and bobbin assembly of the rotary hook machine

Fig. 10: The dismantled bobbin, case and holder of the rotary hook machine

The most ingenious introduction of the late 1880s was the 'Nouvelle machine à fil continu' (the new continuous thread machine). The name implied that it could use continuous supplies of thread like the Grover and Baker stitch machines. However, it was merely a rotary hook lockstitch machine with a larger than usual bobbin, so that bobbin winding was required less often than with most machines. Apart from the complicated bobbin assembly, the machine was a copy of the layout of the Wheeler and Wilson No. 8 rotary hook machine. The machine came in two sizes; A (smaller) and B (larger). For those who could not cope with the bobbin assembly there was a very similar vibrating shuttle version.

Fig. 8: The 'Nouvelle machine à fil continu' size A machine of the 1880s

Sometime before 1890, an engineer, M. Diligeon, joined the company which was rebranded as Hurtu, Hautin & Diligeon. With Diligeon in charge, the company built a new factory in the town of Albert, Somme, while keeping their showroom at 33 Boulevard Sébastopol in Paris. They diversified into making machine tools, bicycles and motor cars as well as sewing machines, becoming one of the largest metal working companies in France. Léon Bollée produced the prototype of his three-wheeled voiturette in Le Mans in 1886. Diligeon acquired the rights to manufacture the Bollée motor-tricycle and several hundred were built by Hurtu, at Albert, up to 1898 when Bollée set up his own factory in Le Mans. The Hurtu name was kept by Diligeon & company who acquired a licence to build the single cylinder Benz car in 1898, from which it derived its own vehicles.

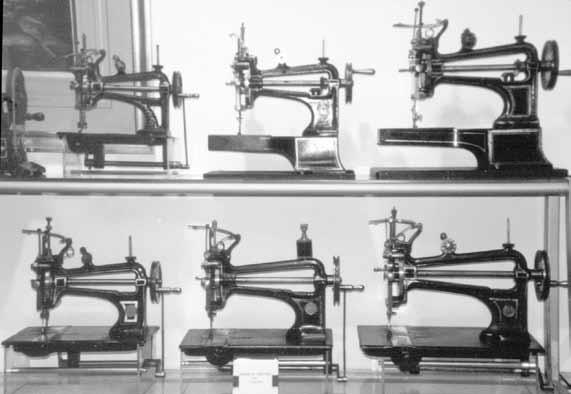

Fig. 6: A display of classic open frame Hurtu machines showing four different arm lengths and both flat-bed and free-arm versions.

At the end of the century, the domestic market was catered for by 'La Moderne', a vibrating cylindrical shuttle machine of conventional enclosed design, available in both treadle and hand versions. There was also a copy of the Wheeler and Wilson No. 9 rotary hook machine. The classic Hurtu open frame machines on their two-pedal treadles were phased out in favour of more modern rotary shuttle machines and the 'Nouvelle machine à fil continu' developed 15 years earlier.

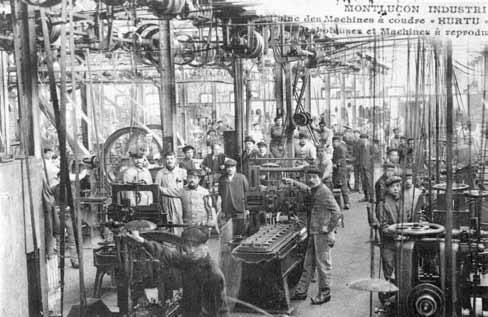

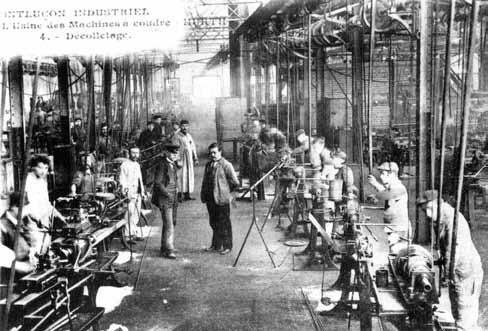

1900 marks the end of significant mass production of sewing machines in France, yet hope existed for a national French plant to produce machines to rival those of Germany and America. Mergers led to a national combine 'Machines à Coudre Françaises - Hurtu' (French sewing machines, [Hurtu]) which built a new factory at Montluçon, Allier in the Massif Centrale. Sadly, this was not a success and the last genuine Hurtu left the factory in 1907. Peugeot, the only other significant manufacturer, had pulled out in 1902. From that point on, effectively all domestic sewing machines sold in France were either Singer or badged imports.

A superb example of the Hurtu "la Productive", from the Maggie Snell collection

The Albert factory was seriously damaged by German shellfire in 1915. After the war, the car and cycle company was reformed and continued to develop the range of cars and cycles. The Paris showrooms were now at 27 Avenue de la Grande Armée and 18 Rue Brunel. In the 1920s, alongside the badged German sewing machines, a toy sewing machine branded Hurtu was marketed but it was presumably bought in from a specialist toy manufacturer.

As with so many companies, trading conditions became very difficult after the Stock Market crash of 1929. No cars were produced after 1929 and that side of the company was formally wound up in 1931. By 1930, the rights to Hurtu sewing machines belonged to one Lucien Rochet who may have continued selling imports for another couple of years.

Martin Gregory

From humble beginnings to mass production