The Howe Sewing Machine

by Martin Gregory

WE ALL know that Elias Howe Jr. invented the lock-stitch sewing machine and took out his master patent number 4750 in the USA on 10th September 1846.

His machine was patented in England by William Thomas under patent number 11464 on 1st December 1846. However, Elias did not try to manufacture machines for another 20 years. It took him about eight years of litigation against other manufacturers to establish his patent fully in the US courts. From 1854 he licensed others to use his patents and from 1856 he exacted a royalty of $5 per machine sold in the USA through the patent combination. These licensing agreements made him a very rich man.

One of the first people to obtain a license from Elias was his elder brother Amasa Bemis Howe (A.B.Howe). Amasa was the brother who took Elias's patent machine to England and sold the rights to William Thomas.

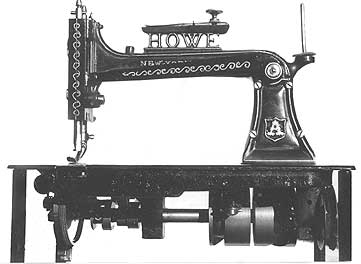

This Howe carries the serial number 24545

Thus, he was no stranger to the sewing machine. In 1854 Amasa set up the Howe Sewing Machine Company (Howe S.M.Co) in New York and started to manufacture sewing machines. He paid Elias and the Patent Combination the appropriate royalty and initially production was on a very modest scale: 60 machines in 1854, 53 machines in 1855.

The machine which Amasa produced is recognisable as the "Howe" sewing machine and is the prototype for the "Howe system" machines which were widely cloned in the 1870s. I do not know what contribution, if any, Elias made to the design of the machine. He had no interest in the company. The patents relating to it which I have come across are in the name of A.B.Howe and not Elias Howe. Production increased very slowly and by 1860 only about 1500 machines had been produced. The photograph of an A.B.Howe machine of 1860 in Grace Rogers Cooper's book (p 93) is of a classic "Howe" machine.

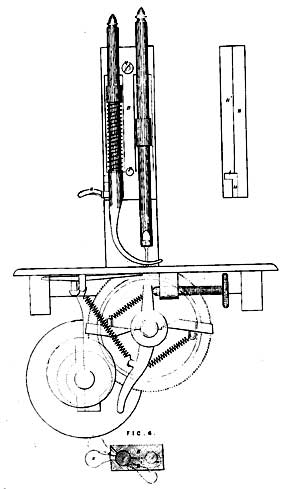

Howe's wheel-feed patent of 1861

The Amasa Howe machines were good well-made sewing machines and after 1860 production increased. The Howe S.M.Co. expanded into Europe with agents in London and Paris.

The London agent from 1860 was Luke McKernan who sold "Howe's sewing machines" at 142 High Holborn and later at 98 Cheapside. In June 1861 the Howe S.M.Co opened its own depot nearby at 8 Ludgate St., St. Paul's with Nahum Salamon as manager. McKernan was clearly upset by the loss of trade and in December 1861 the Howe S.M.Co took McKernan to the High Court for an injunction to restrain him.

It appeared that McKernan's shop window carried the words 'LUKE McKERNAN, late AGENT FOR THE HOWE SEWING MACHINE' in very large letters except for the word 'late'. The Howe S.M.Co was granted its injunction!

A.B.Howe took out patents in England (patent number 1987 of 9th August 1861 and number 2086 of 21st August 1861) for improvements to his classic "Howe" machine.

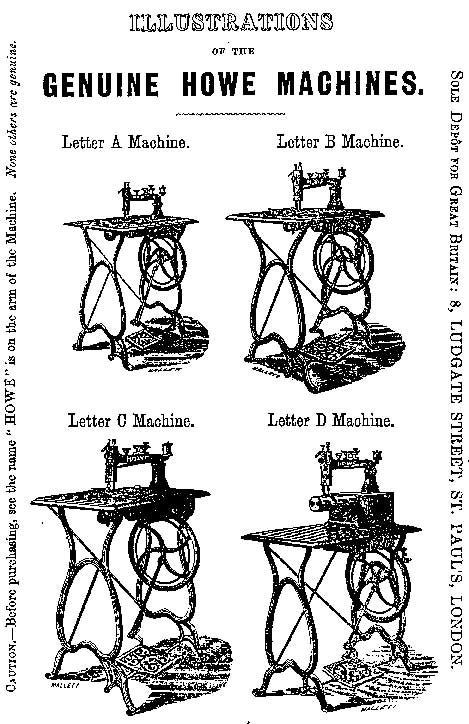

The machines were exhibited on their own stand at the London Exhibition of 1862 where Amasa Howe (not Elias Howe) was awarded a prize medal for the Howe S.M.Co machines and four medals for the excellence of work carried out on them. In 1863 Nahum Salamon, their manager in London, wrote a history of the sewing machine including a biography of Elias Howe, to promote sales of the "Genuine Howe Machines" made by the Howe S.M.Co.

They were advertised as 'Established 1845, perfected 1862'. It is in this booklet that we see the well-known advertisement for "Genuine Howe sewing machines" with four machines labelled A, B, C and D. The 1863 prices in England were:

* "Letter A" for families and light manufacturing. 10 10s (10.50)

* "Letter B" larger, for bootmakers, tailors, dressmakers, etc. 12 10s (12.50)

* "Letter C" a very powerful machine for leather and harness work. 15 (15.00)

* "Letter D" a new small sized cylinder machine (free-arm machine) 18 18s (18.90)

* "Letter E" the unrivalled Howe cylinder machine (free-arm machine) 28 (28.00)

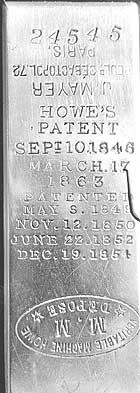

From the Howe S.M.Co machines exported to France, the picture shows an Amasa Howe machine whose shuttle cover plates both carry two die stamps. The first reads "VERITABLE MACHINE HOWE, DPOS, M.M" (Genuine Howe machine, registered, M.M) in an oval.

The second reads "J.MAYER, BOULD SBASTOPOL 72, PARIS being the name and address of their agent. There was a Moses Mayer (M.M) at 82 Boulevard Sbastopol who registered French patents in 1856, 1857 and 1861 so I think it likely that Mayer, M. and/or J. were the agents for the Howe S.M.Co in Paris in the 1860s.

With the Howe S.M.Co machine of 1862 becoming more successful and being made in larger numbers, Elias, who was by then very wealthy, offered to go into partnership with Amasa.

Their collaboration was short lived and Elias soon left to start another "Howe" company with his sons in law, the Stockwell

Brothers. Since Amasa Howe had used the Company name Howe Sewing Machine Company for many years, the new company called itself the Howe Machine Company (Howe M.Co). The Howe S.M.Co continued to build its machines in New York whilst the Howe M.Co set up a large new factory in Bridgeport, Connecticut.

Shuttle cover plate shows patents from 1846 to 1854. This machine was sold by a retailer in France

The Howe S.M.Co continued to develop its machine with A.B.Howe patenting further improvements in 1866 and his son, Benjamin Porter Howe, patenting improvements in 1868, 1869 and 1871. (These are English patents. I presume there are equivalent US patents a month or so earlier but I have no detailed list of these). In England the company also sold the 'Swiftsure' and 'Little Howe' hand machines and a curious rotary hook version of the 'Swiftsure' for which the patent was granted to James Starley. I do not know where these machines were made. They are quite unlike the classic "Howe" machine.

Production by the Howe S.M.Co rose slowly and only reached 20,000 per year in 1871. In 1873 B.P.Howe sold the Howe S.M.Co to the Howe M.Co and the production of "Genuine Howe Machines" stopped. It is thought that about 100,000 machines in total were produced.

The Howe M.Co was on a much larger scale. Its basic machine was a very close copy of the Amasa Howe machine of the day.

The differences; the fluted wheel top tension in place of a spring strip, the shuttle driven from the heel and the presser-foot lifter were the subject of patents by Elias Howe in 1866 (English patents 1798 and 2630). They were Elias Howe patents ascribed to the Howe M.Co. Elias died a year later in 1867. After his death the Howe M.Co was continued by the Stockwell brothers who put a brass medallion featuring a portrait of Elias on their machines.

Production rose rapidly, overtaking that of the Howe S.M.Co by 1868 and reaching half a million in total by the time the Howe M.Co bought the Howe S.M.Co in 1873. Well over one million machines had been produced by the time the company closed in 1886.

The Howe M.Co, copying the Singer Company, set up a manufacturing plant in Avenue Street, Bridgeton, Glasgow in 1873. Amongst the machines it produced for the English market was a hand machine version of the treadle Stockwell Brothers machine, complete with brass medallion.

It is the Stockwell Brothers machine with its brass medallion that most modern collectors think of as the "Howe" machine.

Just as the Wheeler & Wilson curved- needle machine and the Singer 'New Family' machine were cloned in Europe as the 'Wheeler & Wilson system' and the 'Singer system', so the 'Howe system' machine was copied extensively.

Grover & Baker made lock-stitch machines in addition to its patented two-thread chain-stitch machines. The Grover & Baker lock-stitch machine was a close relative of the 'Howe system' and was also copied by German manufacturers.

In England, Bradbury of Oldham had its 'Letter A' and 'Letter B' Howe machines as did Jones of Guide Bridge. Even small manufacturers like Owen Robinson of Kettering produced a 'Howe system' copy. Numerous German manufacturers produced 'Howe system' copies well into the 1880s. The 'Howe system' became one of the three popular layouts for sewing machines from the early days.

It was, however, the first to disappear as real mass production of better machines took hold.

The characteristics of the 'Howe system' machine

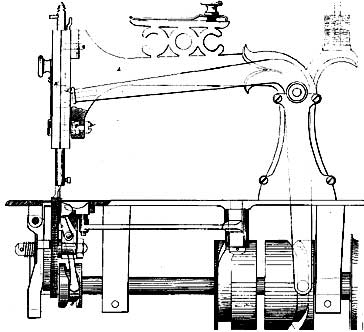

The characteristics of the "Genuine Howe machine" include the use of two bell cranks to drive the boat shuttle and needle bar from two large cast-iron grooved cams on a single shaft below the table.

The use of grooved cams to produce the complex motions of needle and shuttle was present on Elias Howe's patent machines.

Except for very late models (after 1870) almost all Howe S.M.Co machines have serrated wheel feed mechanisms rather than A.B.Wilson's four-motion feed as used today.

Wheel feed was universal until A.B.Howe obtained a patent (number 1874 of 18th July 1866 in England) for a reciprocating feed as an alternative kit to replace the wheel feed.

It was 1869 before B.P.Howe obtained a patent (number 2855 of 1st October 1869 in England) for a proper four-motion feed for the Howe S.M.Co machine. The Howe M.Co copies came with either wheel feed or four-motion feed from a similar date.

The use of two such large cast-iron cams makes the machines heavy and, unless they are regularly cleaned and lubricated, there is a lot of friction and wear. Thus they require more effort to operate them than does the competition.

With the only shaft below the table, no flywheel is accessible and the only way of moving the needle up or down when starting or stopping is to pull on the belt below the table.

This drawing is taken from Howe's British patent application number 1987 of 1861

The stitch length adjustment is also below the table. The use of a wheel feed is very positive for heavy work with heavy-weight fabrics and leather but is less desirable for domestic machines.

It is more difficult to sew curved seams because the feed wheel remains above the surface even when not feeding. The feed is only on one side of the needle.

The Amasa Howe Letter A machine shown (number 24545) was made in the mid 1860s and represents a typical "Genuine Howe machine".

The shuttle cover plate lists Elias Howe's patent (number 4570) of 10th September 1846, Amasa Howe's patent (number 37913) of 17th March 1863, and four other patents held by the patent combination.

The last four show that the Howe S.M. Co paid its dues to the patent combination.

The machine incorporates all the improvements specified in Amasa Howe's patents of 1861 and 1863 (I do not have a copy of the US 1863 patent).

On the front of the over arm is cast NEW YORK, USA. and on the back "I SERVE"- I TIRE NOT.

The picture shown in Carter Bays' book (p 109) is of an almost identical machine which has a different support for the top tension strip and the presser-foot lifting lever is at the front, thus fitting the improvements of B.P.Howe's 1868 patent (number 2473 of 7th August in England).

So, here are some questions.

* What, if anything, does the classic "Howe" sewing machine owe to Elias Howe Jr? How much of its design is due to Amasa rather than to Elias?

* What is the history of the Howe S.M.Co in France?

* What other machines did the Howe S.M.Co produce?

Around 1870 in the reign of Amasa's son B.P.Howe, the Howe S.M.Co marketed in England three hand machines: the "Swiftsure" (patented 1869) and its successor, the "Little Howe", plus the rotary hook derivative patented by James Starley (number 1678 of 21st May 1868).

Were these three machines made by Starley, or some other English manufacturer, and badged for the Howe S.M.Co or were they imported from the USA? I can find no 1869 English patent relating to the "Swiftsure".

An English patent (number 3326 of 31st October 1868) by J.H.Cazal shows an electric motor driving the rotary hook version and refers to it as driving an 'American sewing machine'.

Answers, please, in the form of articles for future ISMACS News Martin Gregory