Wanzer's Sewing Machines

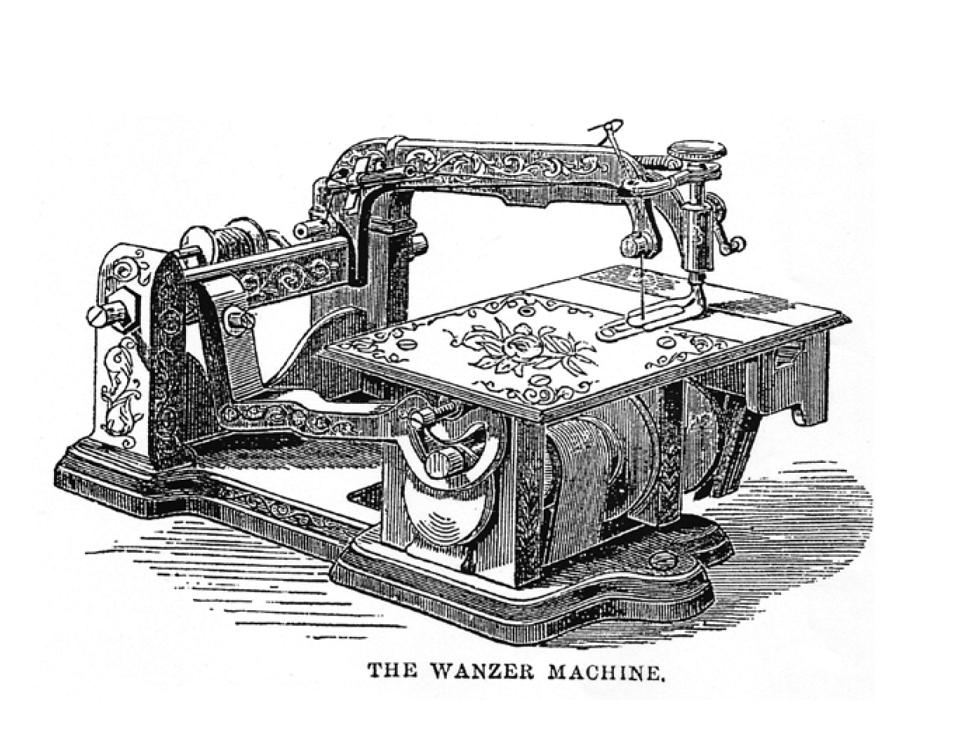

A woodcut from Chambers' Cyclopaedia

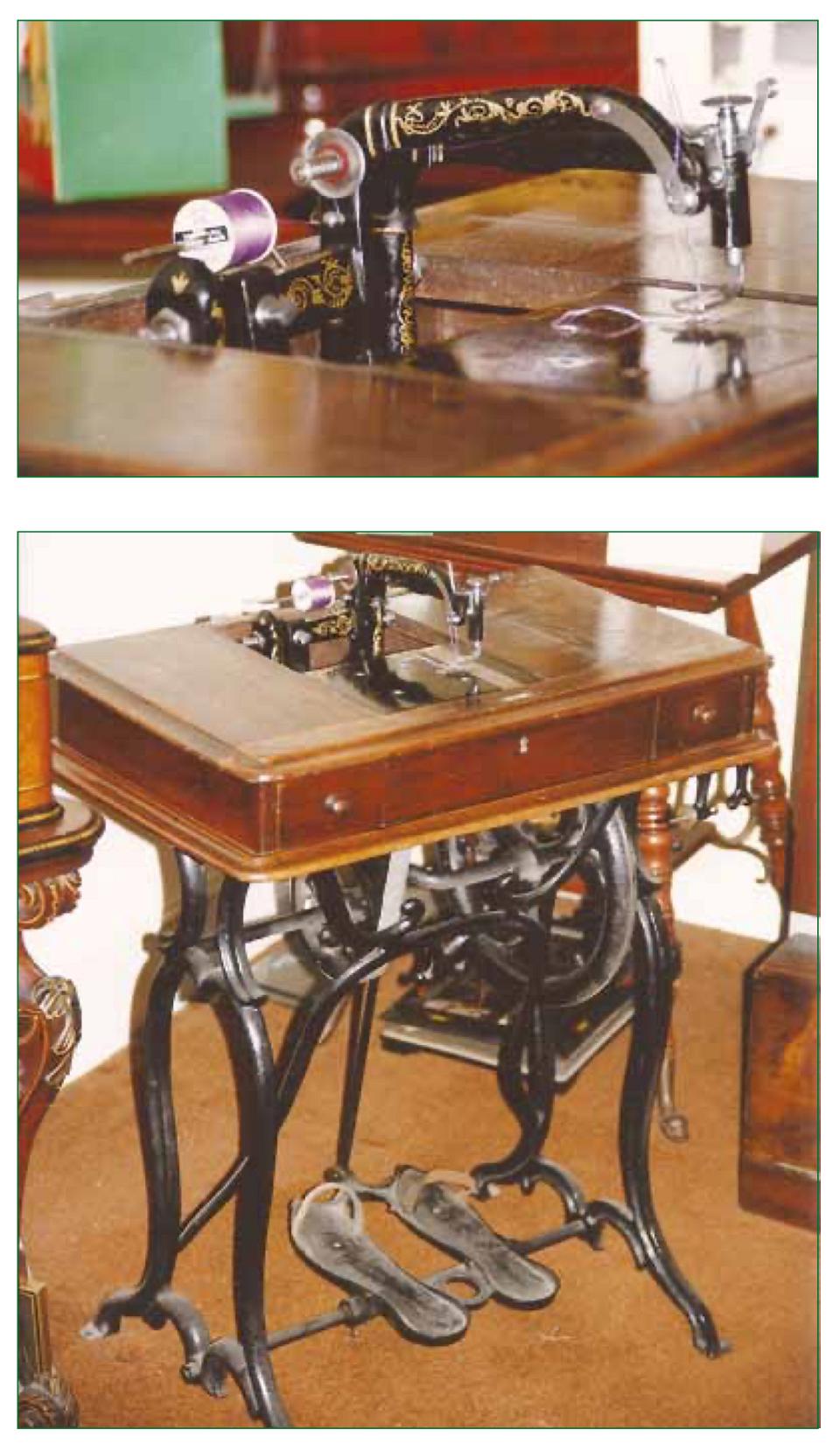

Two photographs of a surviving "Family Shuttle Sewing Machine" on its stand. The machine is recessed into the woodwork so that the table is flush with the clothplate. It sews from left to right rather than front to back.

The most successful of Canada's sewing machine manufacturers was Richard Mott Wanzer. R. M. Wanzer was born in upstate New York in 1818. After a career in teaching, bookselling and, possibly, repairing sewing machines, he immigrated into Upper Canada about 1859 and settled in Hamilton, Ontario.

Backed by the Hamilton iron founder Edward Gurney, he set up the first sewing machine manufactory in Canada in 1860. His partner, John Neil Tarbox, also appears with Wanzer on the early patents.

In 1862 they launched the "Family Shuttle Sewing Machine" which claimed to embody the best of the Wheeler & Wilson and Singer machines. It was a shuttle version of the Wheeler & Wilson curved needle machine. Prior to the Patent Act of 1872, Canadian manufacturers could copy US patents without fee and were outside the grasp of the Patent Combination. They also had tariff free entry to the British market so Wanzer prospered.

The "Family Shuttle Sewing Machine" was joined in 1868 by the "Little Wanzer"; a cheap little machine which retailed for $25 on a marble block or $30 on a treadle. By 1870, Wanzer had erected a new factory which was capable of producing 1000 machines per week. Judged by the catalogue of 1874 the range had been expanded to seven machines. The "Little Wanzer" was awarded a gold medal at the American Centennial exhibition in 1876. He bought out his partner Tarbox in 1875 and built another factory to increase production to 1500 machines per week by 1881.

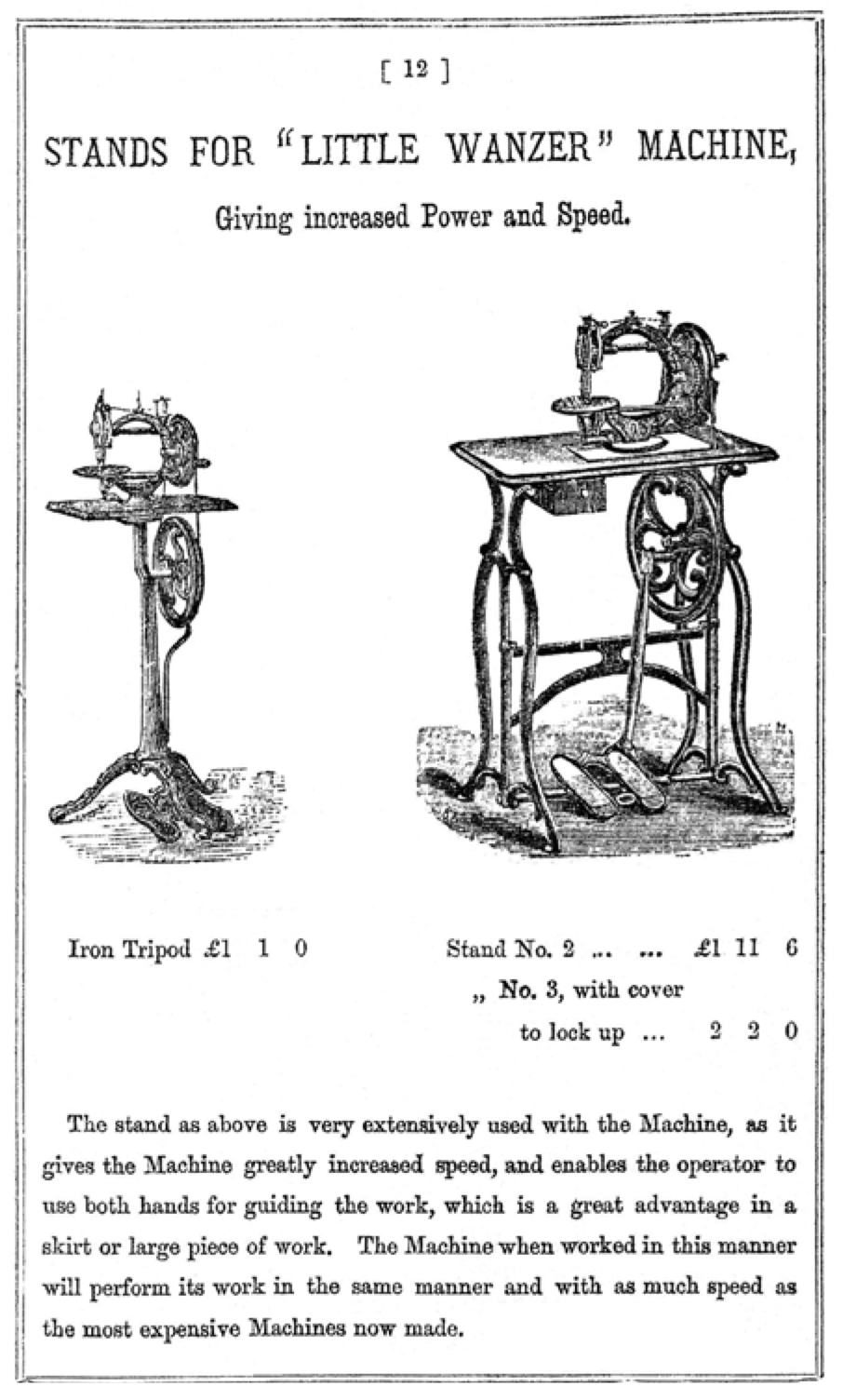

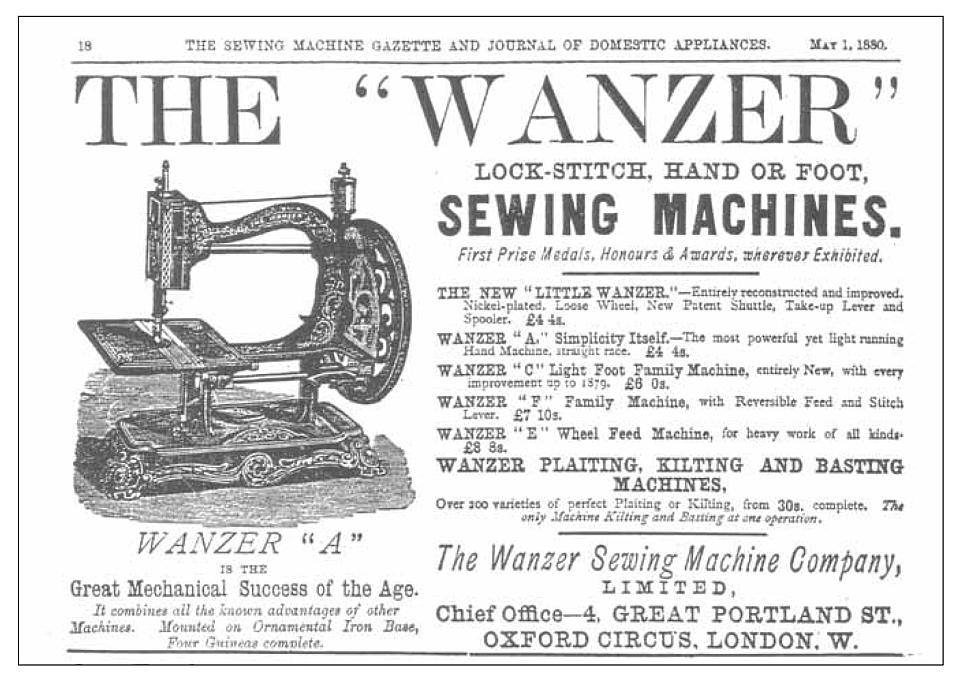

He spent a lot of time expanding his markets in Britain and Europe. Machines, imported in parts, were assembled in England. The head office was at 4 Great Portland Street, London W. The "Little Wanzer" proved very popular at 4 guineas (£4.20) and was adopted as the standard instructional machine for all 7500 Irish national schools. This, and the "Wanzer A", were the most popular models; both were the same price and were available on the same treadles and stands. The bigger Family models are much less common in England.

During the 1880s, competition from budget American machines and a drop in demand in Britain and Europe, led to hard times for the company. Wanzer diversified into Colza lamps, cookers and soap but it was not enough to keep the company afloat. R. M. Wanzer & Company failed in 1890 and the ruined Wanzer left Hamilton for Buffalo NY where he tried to rebuild his fortunes. It is estimated that he made 1.5 million sewing machines in Hamilton between 1865 and 1890. None of his American ventures came to anything and he died in New York City in 1900. He is buried in Hamilton.

The Machines

The "Family Shuttle Sewing Machine" was only available on a treadle. It was patented in Canada and England (No. 1605 of 1863) by Wanzer and Tarbox as a direct competitor to the Wheeler & Wilson curved needle machine. Indeed, it used the same needles and glass presser foot inserts! It was phased out by 1870 when more conventional successors came to market.

"Little Wanzer" on the popular single pillar stand. This one has a walnut rather than a cast iron top.

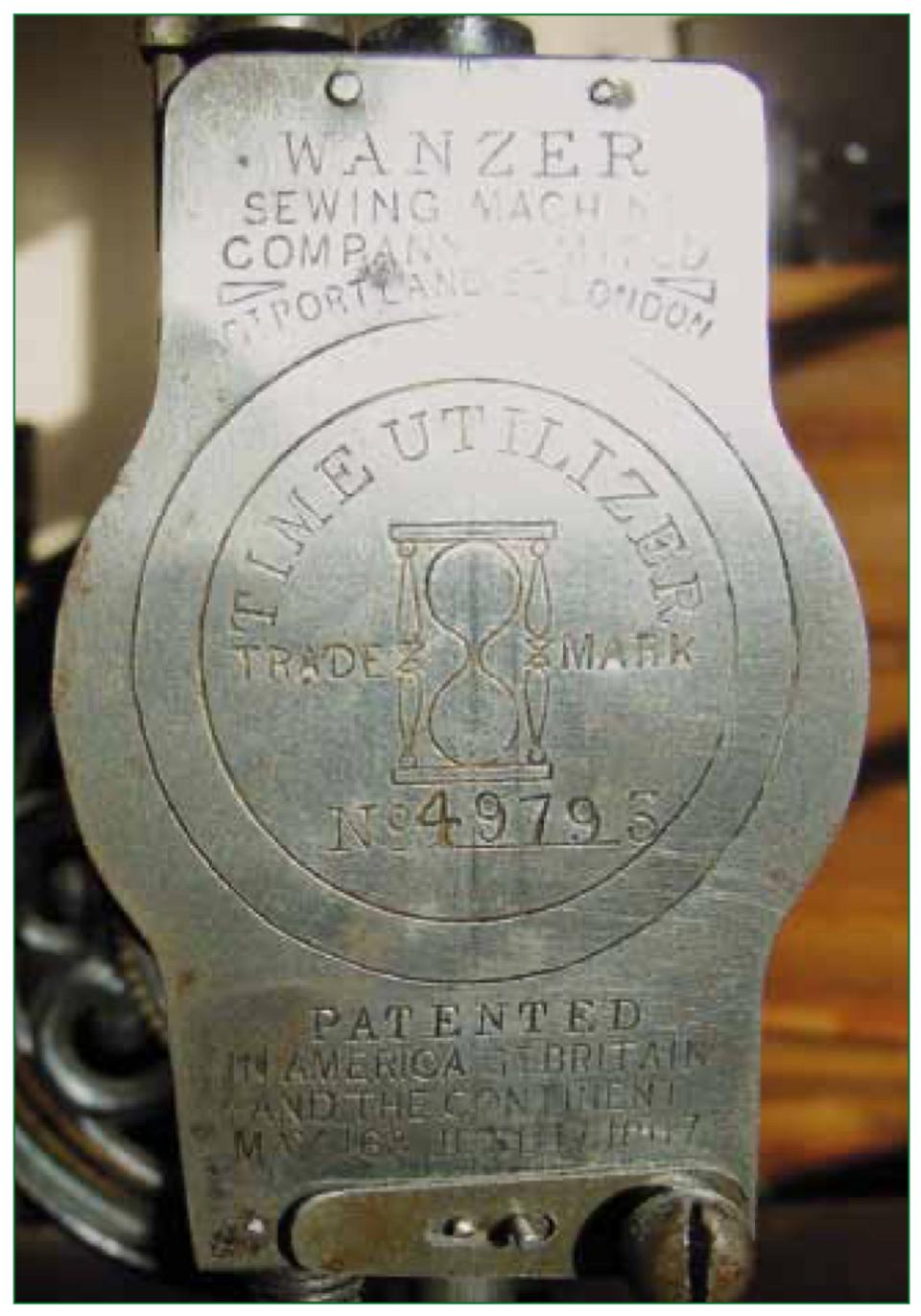

The "Little Wanzer" is by far the best known of the Wanzer range. Four thousand were produced in the first year (1868) and production continued well into the 1880s. The simple shuttle mechanism enabled the user to extract the shuttle below the clothplate without any slide in the clothplate. The frontplate, originally brass and later steel, carried Wanzer's trademark of an eggtimer and the slogan "Time Utilizer". The only upgrade came in 1881 with the "Little Wanzer SR" with a straight (shuttle) race and improved top tension and takeup, modelled on the "Wanzer A". The most collectable version is on a single pillar cast iron stand. Machine + stand was 5 guineas (£5.25) with a cast iron table top and £5 - 14s (£5.70) with a walnut top.

The frontplate on the "Little Wanzer" showing the Wanzer trademark

A typical "Little Wanzer". Wanzer did not use a high quality varnish and surviving machines often have little decoration left!

Two stands illustrated in the instruction book

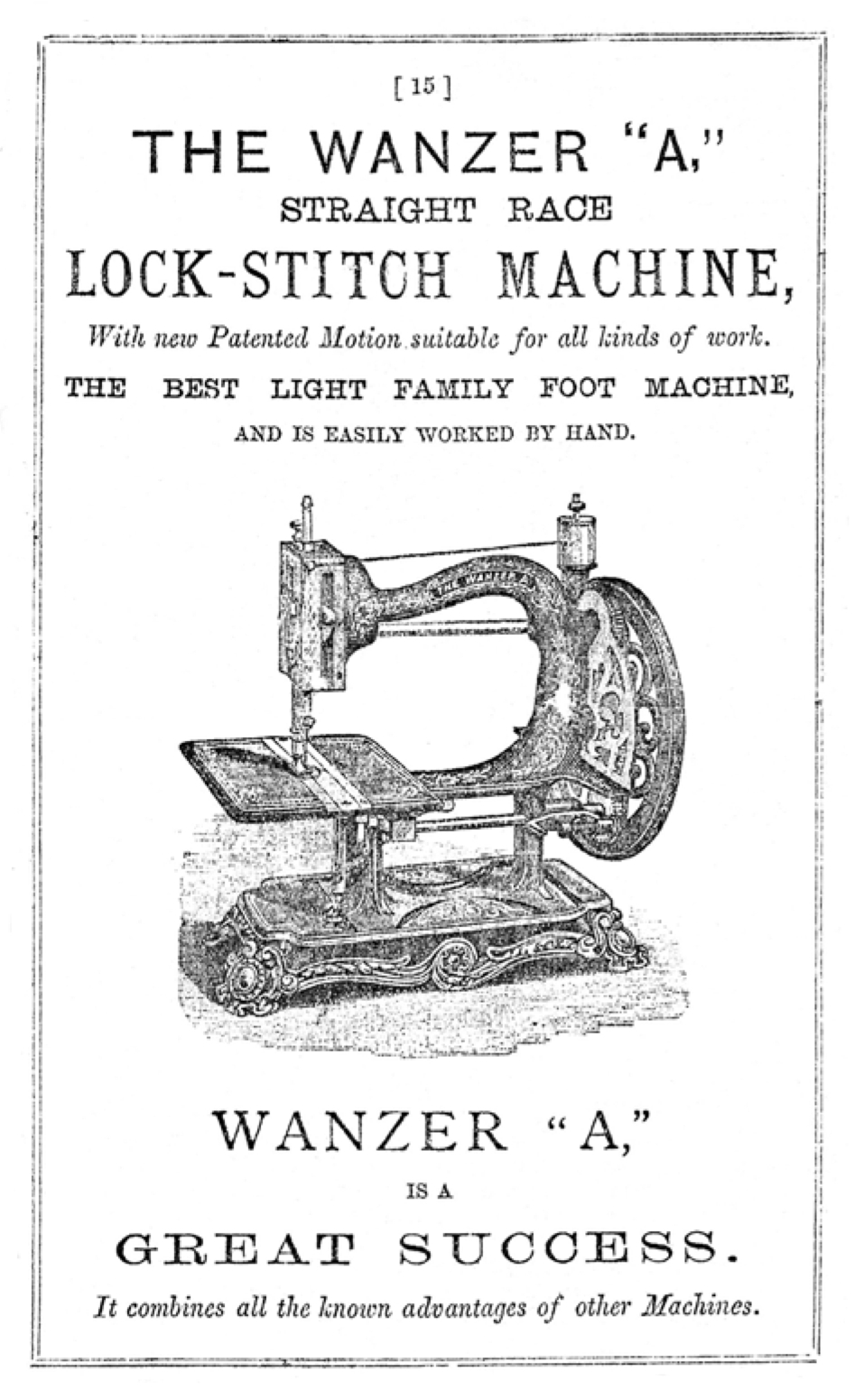

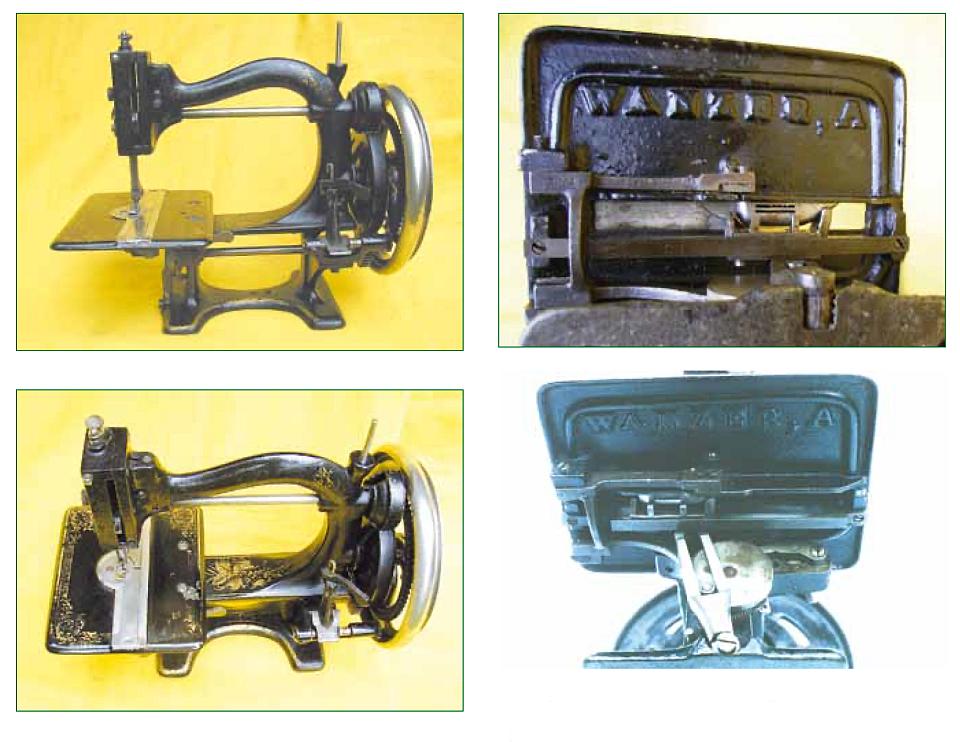

The "Wanzer A" was a little bit bigger than the "Little Wanzer" and had a straight shuttle race and rectangular clothplate. It is usually found on an ornate cast iron base. The same treadles and stands were used.

An illustration of the "Wanzer A" from its instruction book.

"Wanzer A" attached to its decorative cast iron base

"Wanzer A" shuttle drive

"Wanzer A" showing the shuttle drive and layout. This one does not have its cast iron base.

The "Wanzer B" came after 1880. It was a larger iron-based hand machine with a vibrating shuttle mechanism similar to many budget American machines.

The Underside of the Wanzer B

"Wanzer B" was a late addition. It was an iron based hand machine with a simple vibrating shuttle layout.

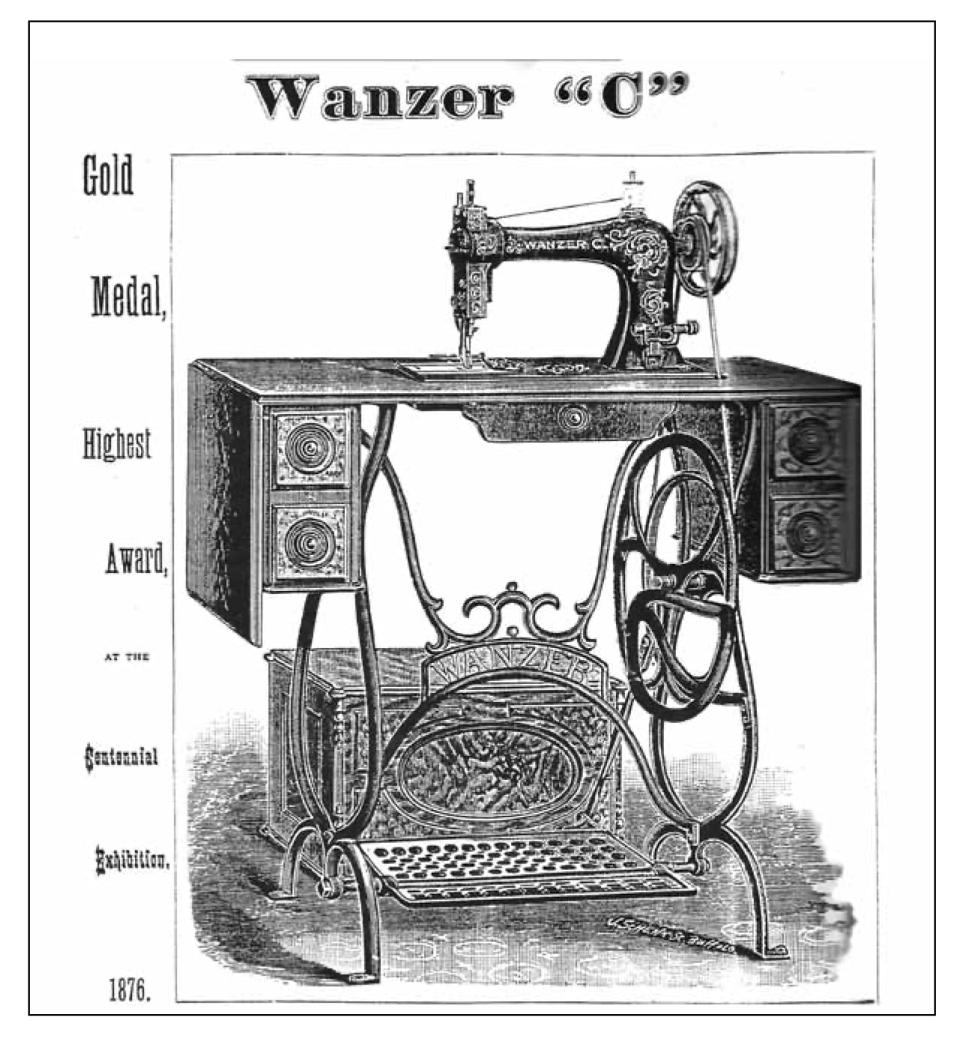

The "Wanzer C" was his final high-arm machine on a treadle stand and aimed at dressmakers. It was fitted with a feed on both sides of the needle, triangular needle bar with integral oil cup and a positive take-up. It was patented in England (No. 3769) in 1882 and, like the "B" was a conventional vibrating shuttle machine, possibly aimed at taking on the American market.

An advertisement for the "Wanzer C" from the Sewing Machine Advance of May 15th 1880.

The "Wanzer E" had a wheel feed for leather work. I have never seen one.

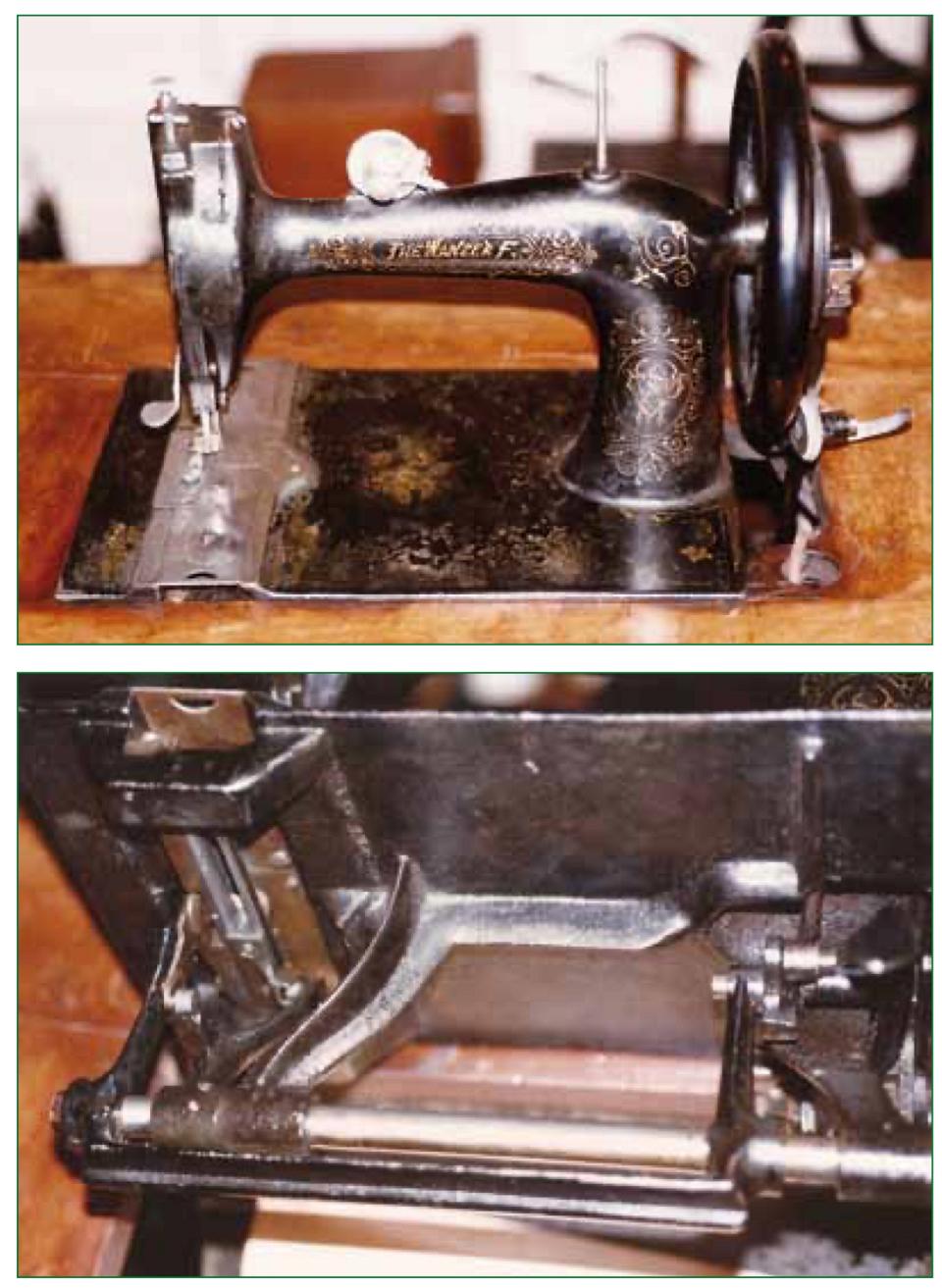

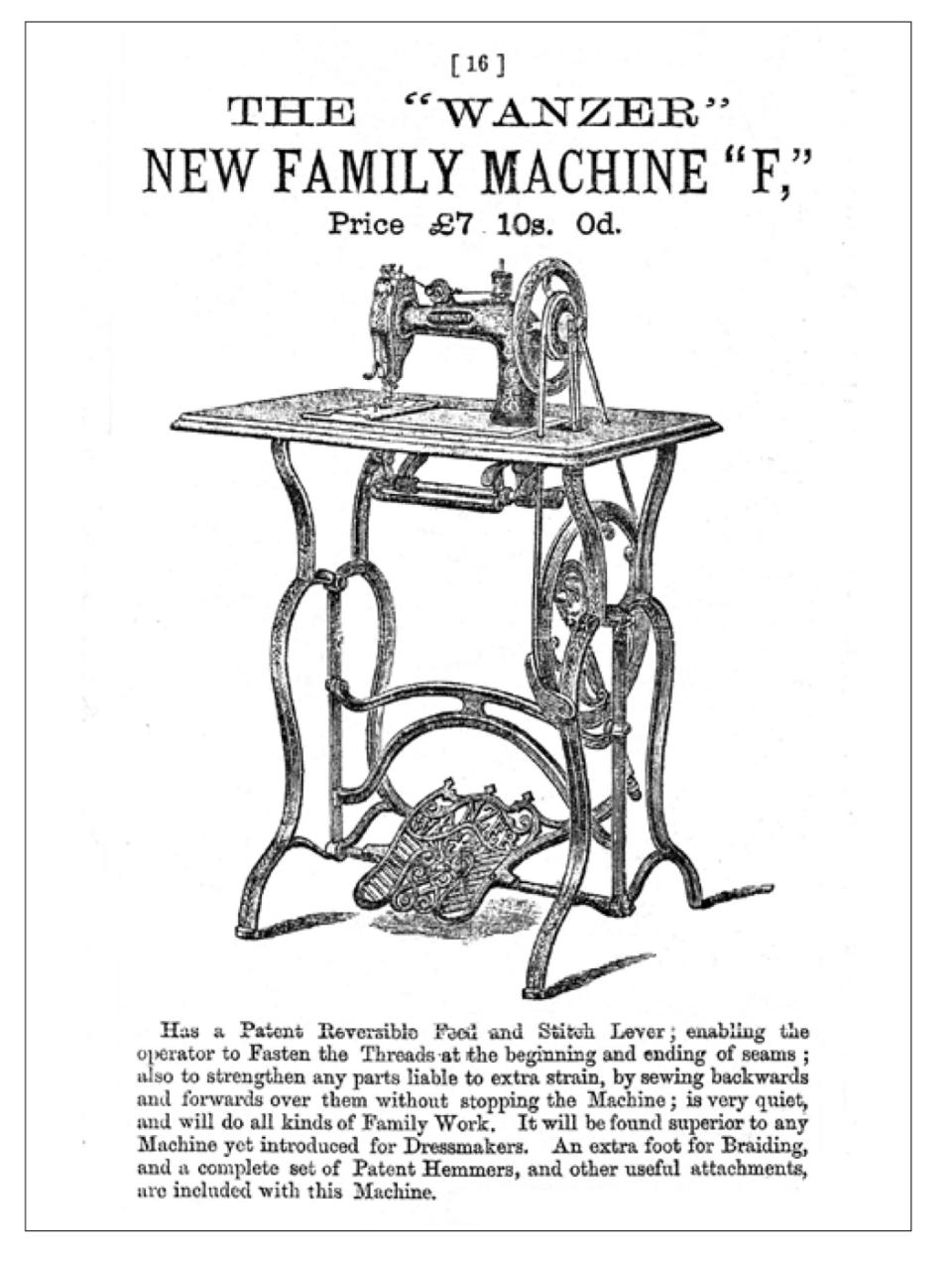

Views of the "Wanzer F". Topside shows a typical high-arm layout of the late 1870s. The underside shows a somewhat clumsy mechanism driving the shuttle though the provision of a reversible feed was ahead of much of the competition.

The "Wanzer F" had a reversible feed controlled by levers underneath the tabletop. The "F" antedated the "C", being patented in England (No. 2420) in 1874 making it contemporary with the introduction of the "A". The layout was characterised by the mechanism projecting well below the bedplate because the shuttle moves in a straight line driven like the "Wanzer A". The rocker driving the shuttle is driven by an external rod outside the pulley, rather than a rod inside the overarm casting.

This feature did not matter when on a treadle but it precluded a hand version. (M.G.)

ISMACS is an organization totally independent of all sewing-machine manufacturers, past or present and is not affiliated with any of the companies mentioned in these pages. Please Note: Do not contact any ISMACS official in an attempt to solicit a valuation - it is not possible other than by hands-on assessment and your request will be ignored.

All rights reserved by ISMACS, under International and Pan American copyright conventions. Reproduction or copy of this page, in any form, in part or in whole, is strictly prohibited, without prior, written permission.