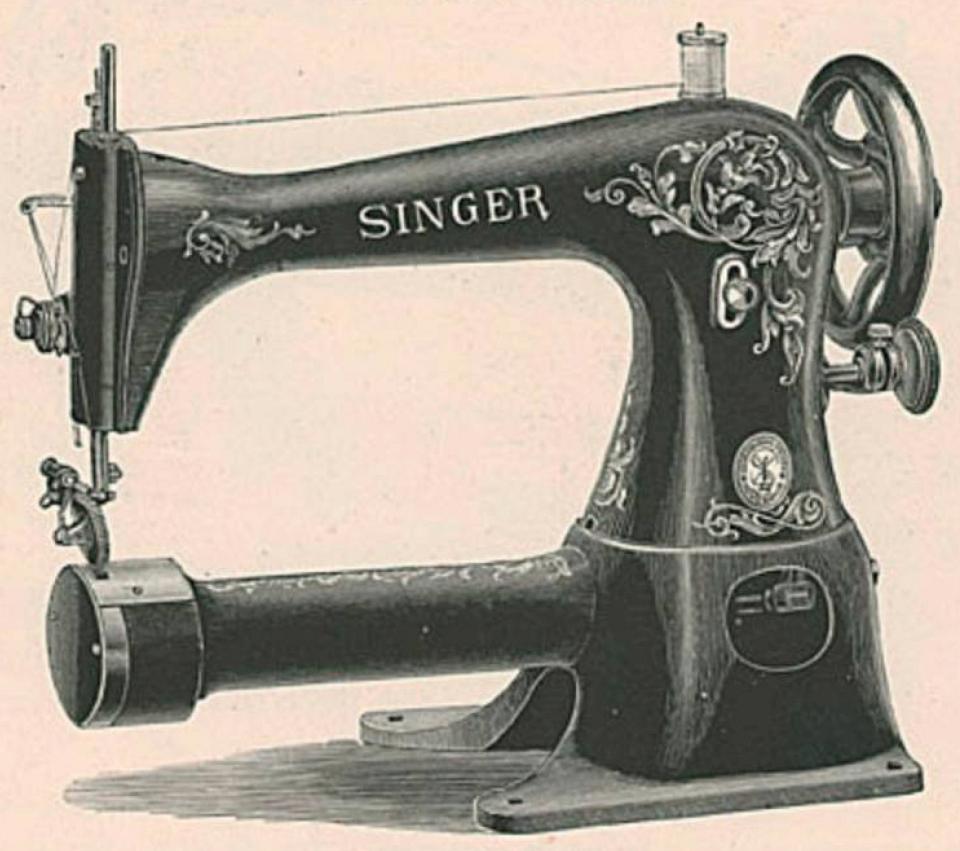

Class 43

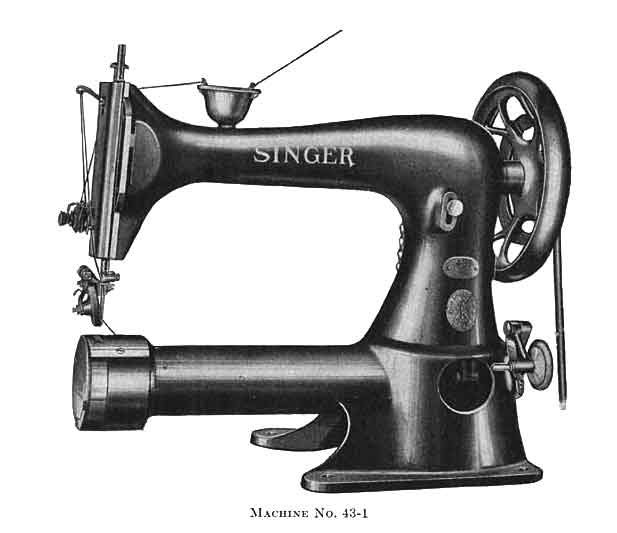

MACHINE No. 43-1.

Cylinder Bed, (right hand: 10 1/2 inches from Needle to Base of Arm. Extra large shuttle for coarse thread and heavy work.

THE machine illustrated above has Oscillating Shuttle, Central Bobbin Roller Presser and Drop-Feed at left of needle; it is intended for stitching leather and for operation by foot-power, but is equally suitable for steam, electricity or other power.

The form and proportions of this machine are such as to secure utmost compactness and lightness consistent with the greatest strength and stability.

The Balance Wheel is 8 1/2 inches in diameter and is arranged for two rates of speed; its increased weight and momentum greatly promote ease of operation and steadiness of motion, so that either thin or thick material can be stitched with the greatest facility.

The Cylinder-Bed or work-supporting arm is 3 3/16 inches in diameter and has 10 1/2 inches clear space from needle to base of arm; it possesses great strength and stability and its shape is especially suited for the easy and convenient handling of heavy fabrics, such as Leather, Canvas, Carpeting, Gunny Bagging, etc. in tubular or concave forms.

The Shuttle is very large and its Bobbin has unusually great capacity for thread. The shuttle and needle-action are located one-quarter inch from outer end of cylinder-bed, thus making it convenient for stitching closely up to buckles or any part of the work which may project or hang downward. The roller-presser is hinged so that it may be thrown up and away from the needle.

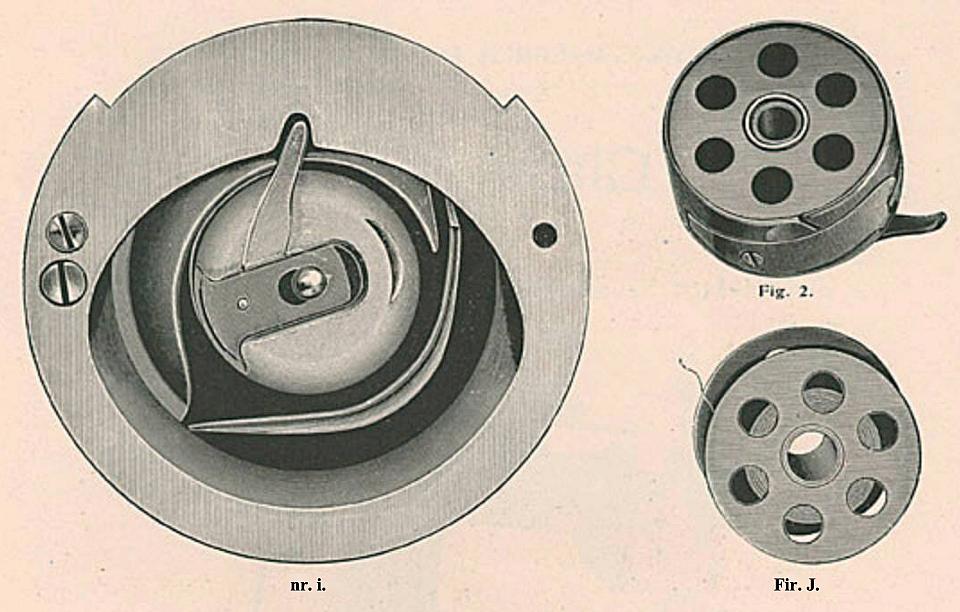

The Oscillating Shuttle in the burnished shuttle-race (Fig. 1), the Central Bobbin in its case (Fig 2), and the Bobbin alone (Fig. 3), are shown at full size in the following illustrations.

The range of stitch is up to one-half inch in length; the needle-bar is provided with a cam and is driven by a roller attached to a cam wheel on the main driving shaft; the motion of Thread Take-up is so regulated as to obtain the best possible results in leather and similar material. A larger size of thread may be used to a given size of needle so that it is possible to use thread that will fill the needle-hole, thus increasing the strength of the stitch.A shorter needle is used than on any other lock-stitch machine of this class.

Machine No. 43-1 is especially adapted to the manufacture of Harness work, Feed Bags for animals, Heavy Boots and Brogans, Dog Collars and similar heavy leather work in a form that cannot be conveniently stitched on a machine having a flat bed.

Machine No. 43-2 is intended for stitching textile fabrics and differs from the preceding description in the following particulars: it has a link connection from needle-bar to cam on main driving shaft; the drop-feed is on both sides the needle, and the yielding presser-bar has a hinged presser-foot, thus adapting the machine for stitching of heavy textiles in tubular or similar forms inconvenient to handle on machines having a flat bed. It is used in the manufacture of Canvas Bags, etc.

Machine No. 43-4 is for leather stitching and is provided with a link needle-bar connection and a long-beak cylinder shuttle.

All the machines in this class have knee-lifter by which the presser-foot can be instantly removed without using the hand.

The following is lifted from John Langdon's Comprehensive Model List

| 43 (class) | Industrial | Central Bobbin (C.B.); 10 1/2" space at right of needle; Large shuttle. Cylinder bed 3 3/16” diameter at end. C. B. models ideally mounted on treadle. | - | |

43-1

|

Industrial | C.B., drop feed at left of needle, roller presser. Speed 400. For leather. | 16x64 | |

| 43-2 | Industrial | C.B., drop feed both sides of needle. Speed 400. For cloth. | 16x63 | |

| 43-3 | Industrial | Drop feed both sides of needle. Speed 400. Long beak cylinder shuttle, vibrating presser. Speed 400. For leather. | 16x64 | |

| 43-4 | Industrial | Long beak cylinder shuttle. Drop feed at left of needle; roller presser. Speed 400. For leather. | 16x64 | |

| 43-5 | Industrial | Long beak cylinder shuttle. Drop feed at left of needle; alternating pressers. Speed 1000. For leather. | 16x64 | |

| 43-6 | Industrial | Cylinder shuttle, upper feed. Speed 400. For stitching sweatbands, cap bands, and visor cushions into the bodies of caps. | ||

| 43-7 | Industrial | For stitching curved visors, sweat bands and cap bands into the into the bodies of caps in one operation. Upper feed. - lifting and vibrating foot(s). No under feeding. Speed 600. Max stitch length 1/4". (03/49) | ||

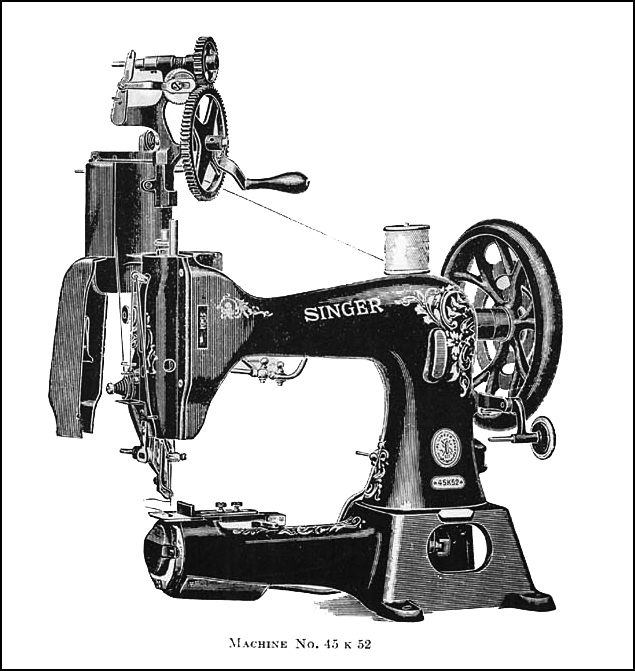

43K52

|

Industrial |