Class 19

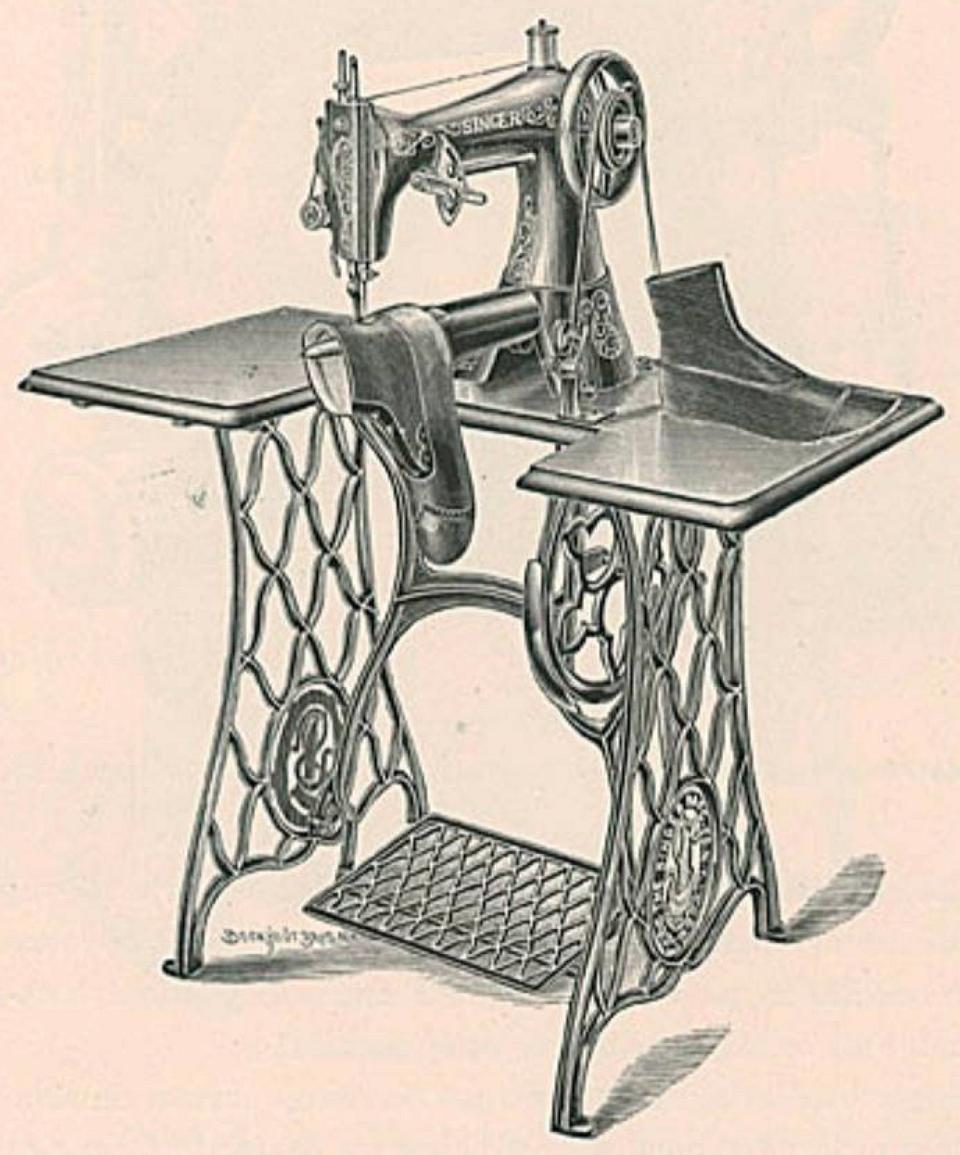

MACHINE No. 19-12

FOR LEATHER.

THE machines in Class 19 have a cylindrical bed 16 1/2 inches in length, with a clear space of 10 1/2 inches from needle to base of arm; the cloth-plate extending outward from the needle varies in length according to the work for which the machine is specially fitted.

The diameter of the work-supporting arm is 2 1/4 inches, excepting in two varieties hereafter specified: there are eleven varieties in the class, but all have drop-feed arranged to feed lengthwise the arm and all have a balance-wheel located on the side of machine convenient to operator's right hand.

The feed mechanism on all the machines of Class 19 is arranged for reverse motion, so that the fabric can be fed either forward or back and a seam can be double stitched at any point. They can be operated by foot or mechanical power, the machine illustrated above (No. 19-12) being mounted on stand for foot-power and having its feed and presser arranged for leather stitching.

These machines are used for stitching elastic gores, back straps and back seams in shoes, for felling, closing or tacking seams in shirts, trousers and knit goods, and are adapted for all work of a similar character in which it is necessary that the thread shall pass from and to the inner surface of hollow forms that can be more conveniently stitched when feeding lengthwise the work-supporting

All the machines of Class 19 have the Oscillating Shuttle mechanism; the varieties numbered 4, 5, 11 and 12 have the long-beak shuttle, and those numbered S, 9, 10, 13 and 14 have a solid shuttle which oscillates about a large central bobbin, other distinguishing features being as follows:

Machine No. 19-13 is for cloth and is used for felling and closing shirtsleeves, overalls and similar work.

No. 19-14 is for leather and is used in Shoe manufacture for inserting back straps and for closing whole vamps.

No. 19-0 has an arm which is only 113 inch in diameter, thus enabling the stitching of cylindrical objects having a small opening.

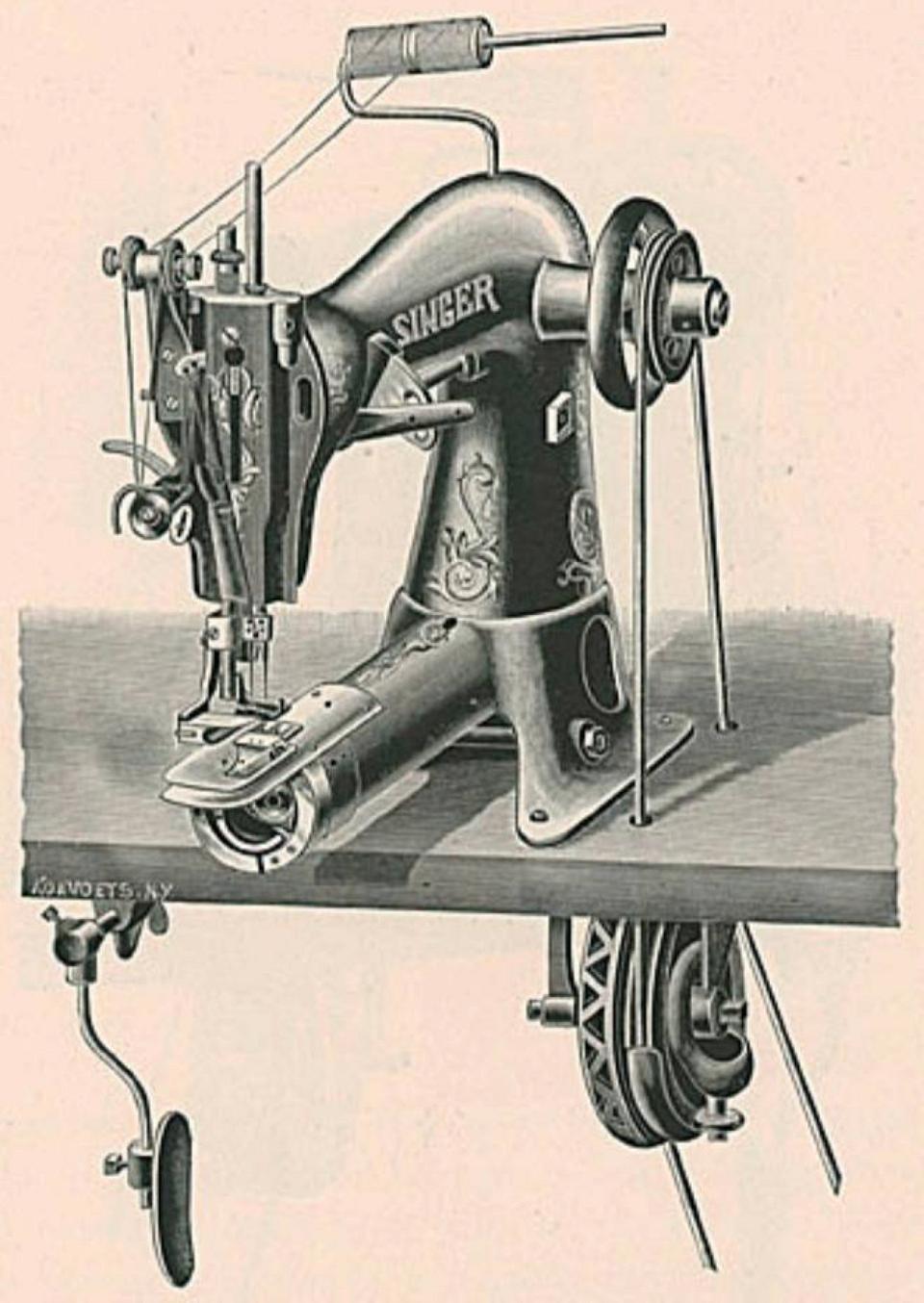

MACHINE No. 19-15

WITH FELLING ATTACHMENT.

The above illustration shows Machine No. 19-15 fitted with hinged lapseam feller (No. 588 (the manual from which this text was taken has the 588 marked out and 592 hand-written) A. and A.) for closing seams on heavy goods in the manufacture of Overalls, Jumpers, etc.

This attachment is commonly known to the trade as "the St. Louis feller;" it is only used on Singer sewing-machines and is of the highest efficiency for its purpose because of its convenience and its automatic adjustability to any variation in thickness of fold or seam.

All parts are yielding and so arranged as to secure the greatest facility for quick handling of work in making straight and perfect seams.

The illustration shows the convenient form of knee-lifter (No. 271 P. T. F.) used on power tables with this class of machines, also the Singer Under Driver (Screw Pressure), the most effective device for its purpose.

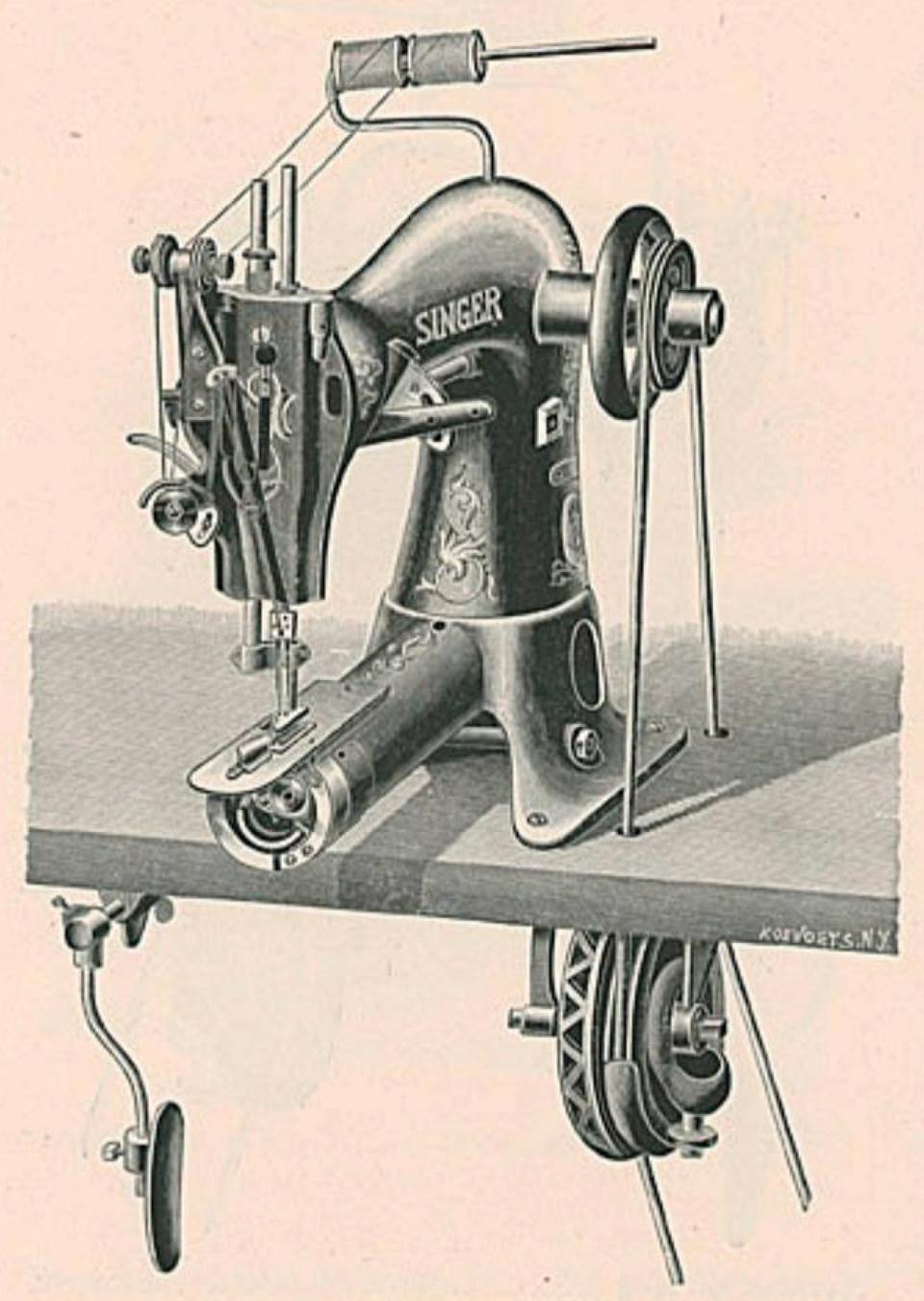

MACHINE No. 19-16

WITH FELLING ATTACHMENT

The above illustration shows Machine No. 19-16 fitted with felling attachment for closing shirts, etc.

Through the use of this attachment, which is peculiar to Singer sewing-machines, perfect seams can be quickly made by any operator using ordinary care.

The seam is more easily started than by any other method and the work is always in sight. The presser is located directly over the seam, which is carried evenly, without puckering or creasing on either side. Owing to its convenience for handling the work much time is gained by the use of this device, thus securing a distinct increase of product as well as improved quality of work.

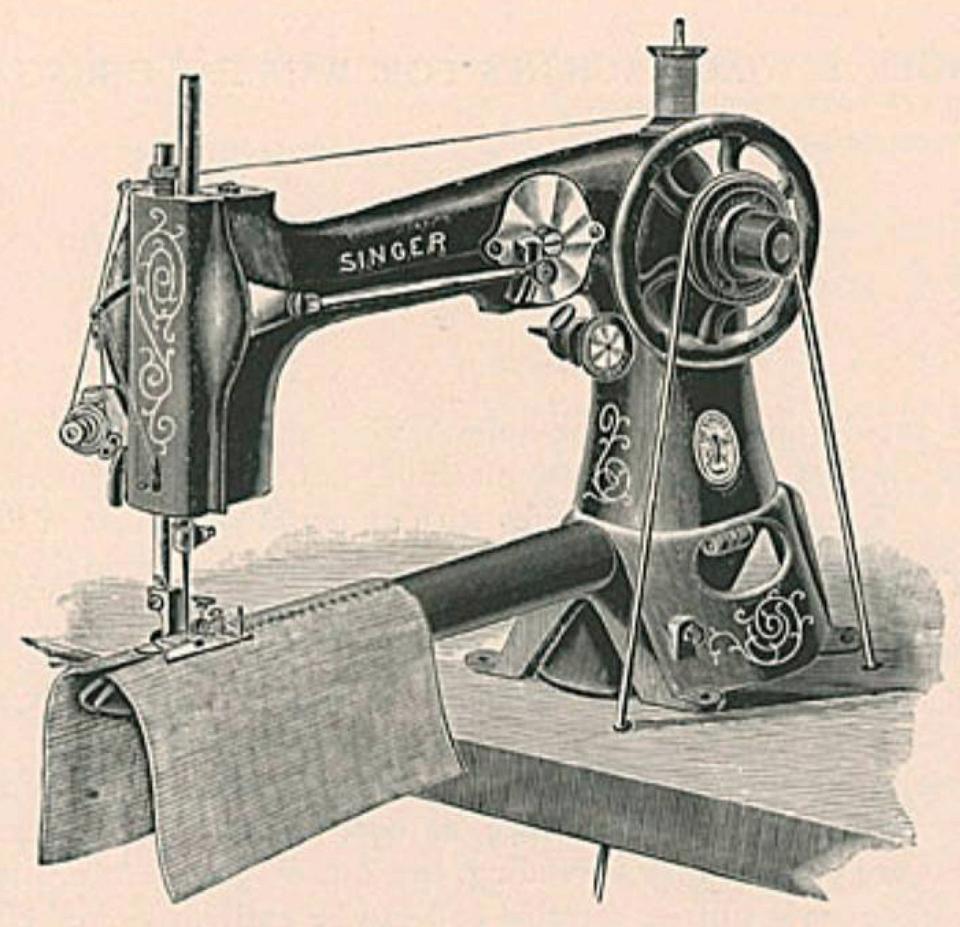

MACHINE No. 19-10

FOR OVERSEAMING

Machines No. 19-8 and No. 19-10 make the zig-zag stitch for overseaming; they only differ in the diameter of the arm, which is 2 1/4 inches on Machine No 19-8 and 1 13/16 inches on Machine No. 19-10; the latter is shown in the above illustration as sewing up a seam on knit goods, for which purpose it is especially adapted and extensively used. The stitch made by these machines produces a flat and elastic seam, uniting two raw edges in a manner that is superior to any other. A special form of combined guide and presser is used (Parts No. 7111); the edge of a separator blade or guide drops into a slot in the throatplate, the raw edges of the fabric are carried against each side of this guide, which is sufficiently far from the feed to prevent its catching the edges. The guide is adjustable and is raised with the presser-foot so that the work can readily be removed.

Machine No. 19-10 is also used for closing the seams of leather cylinders, the edges of which are strongly and squarely united by the ornamental zig-zag stitch; it is used in the manufacture of round leather boxes or other stitching of a similar character. The diameter of the cylinder permits the closing of a small aperture.

The following is lifted from John Langdon's Comprehensive Model List

| 19W (class) | Industrial | Rotary long beak hook, rotating ball bearing feed and presser foot. Adjustable bight. Rotary presser foot; raised or lowered by foot.Bed 17 3/4" long. 10 7/8” space to the right of needle. For working eyelets in textiles and leather. | - | |

| 19 (class) | Industrial | Cylinder bed. Side wheel. Feed up or off the arm. Oscillating shuttle. Knee or foot lifter. 10 1/2" space to rear of needle. | - | |

| 19K | 1899 - 1907 | |||

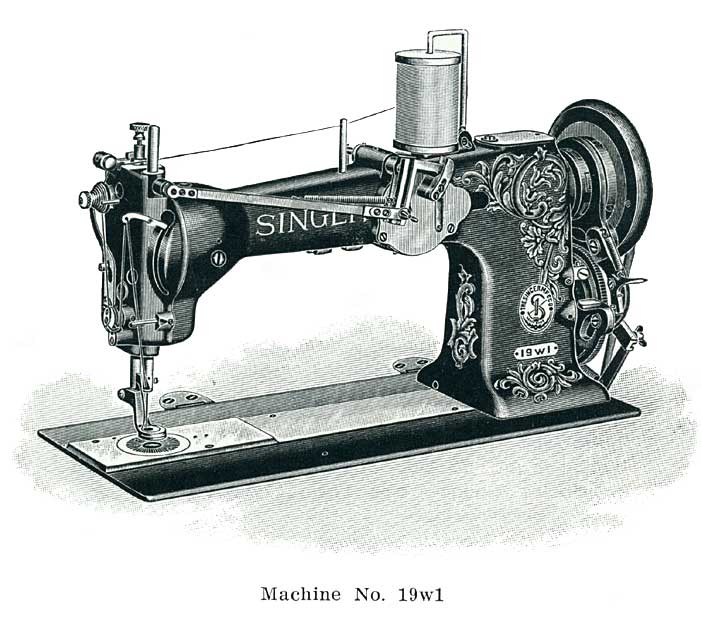

19W1

|

(Cancelled 07/1948) | Industrial | For making eyelets in fabrics or leather. Space to right of needle = 10 7/8". "Makes one radial stitch at each movement of the rotating feed during the first revolution of the clamp, then the radial stitches are locked at the desired distance from the centre of the eyelet by an intersecting line of stitches as the clamp makes its second revolution...". Singer suggested replacement 19W4. | 126x1 |

| 19W2 | (Cancelled 07/1948) | Singer suggested replacement 19W4. | ||

| 19W3 | (Cancelled 07/1948) | Singer suggested replacement 19W4. | ||

| 19-4 | Industrial | Drop feed. Two needles, one shuttle, 1/32" to 3/16" gauge. Makes two parallel seams on upper surface and an overcast or "stay" stitch on the under surface. Speed 1200. For leather. | 19x2; 19x4; 19x6 and 19x6; 16x2 or 16x22 | |

| 19-5 | Industrial | Drop feed. Two needles, one shuttle, 1/32" to 5/16" gauge. Speed 1200. For cloth. | 16x1 or 16x2; 16x21 or 16x22 | |

| 19-8 | Industrial | C.B. over seaming, drop feed. Speed 1000. For cloth or leather. | 16x73 or 16x74 | |

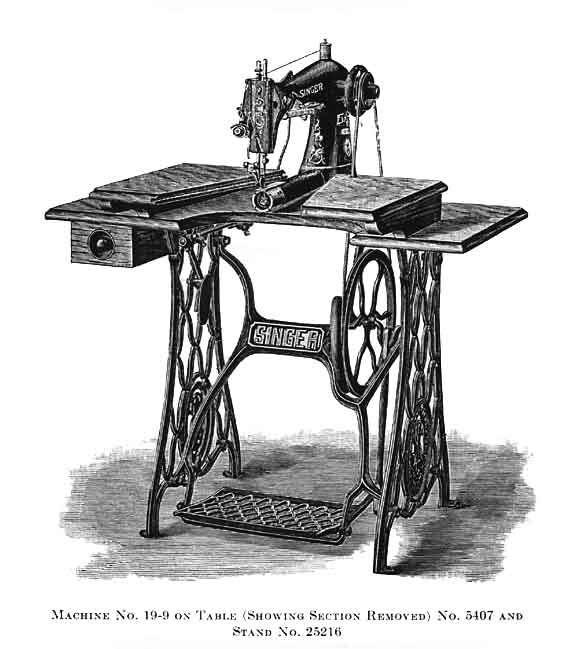

19-9

|

Industrial | C.B., cylinder bed 1 13/16" diameter at end. Drop feed. Speed 1200. For cloth or leather. | 16x73 or 16x74 | |

19-10

|

Industrial | C.B. Drop feed. Over seaming cylinder bed 1 13/16" diameter at end. For cloth or leather. Speed 1000. | 16x87 (2055) | |

| 19-11 | Industrial | Drop feed. reversible. For cloth. Speed 1200. | 16x1 | |

| 19-12 | Industrial | Drop feed. reversible. For leather. Speed 1200. | 16x2 | |

| 19-13 | Industrial | C.B. Drop feed. reversible. For cloth. Speed 1200. | 16x73 | |

| 19-14 | Industrial | C.B. Drop feed. reversible. For leather. Speed 1200. | 16x74 | |

| 19-15 | Industrial | Two needles, two shuttles. Drop feed. Low bed. For cloth. | 16x45 or 16x51 | |

| 19-16 | Industrial | Two needles, two shuttles. Drop feed. Low bed. For closing shirts. | 16x1 or 16x21 | |

| 19-17 | Industrial | Two needles, one C.B. shuttles. Makes two parallel seams on top surface and overcast stitch beneath. Drop feed. For shoe work. | 19x10; 19x12; 19x13 and 19x16; 16x74 or 16x86 | |

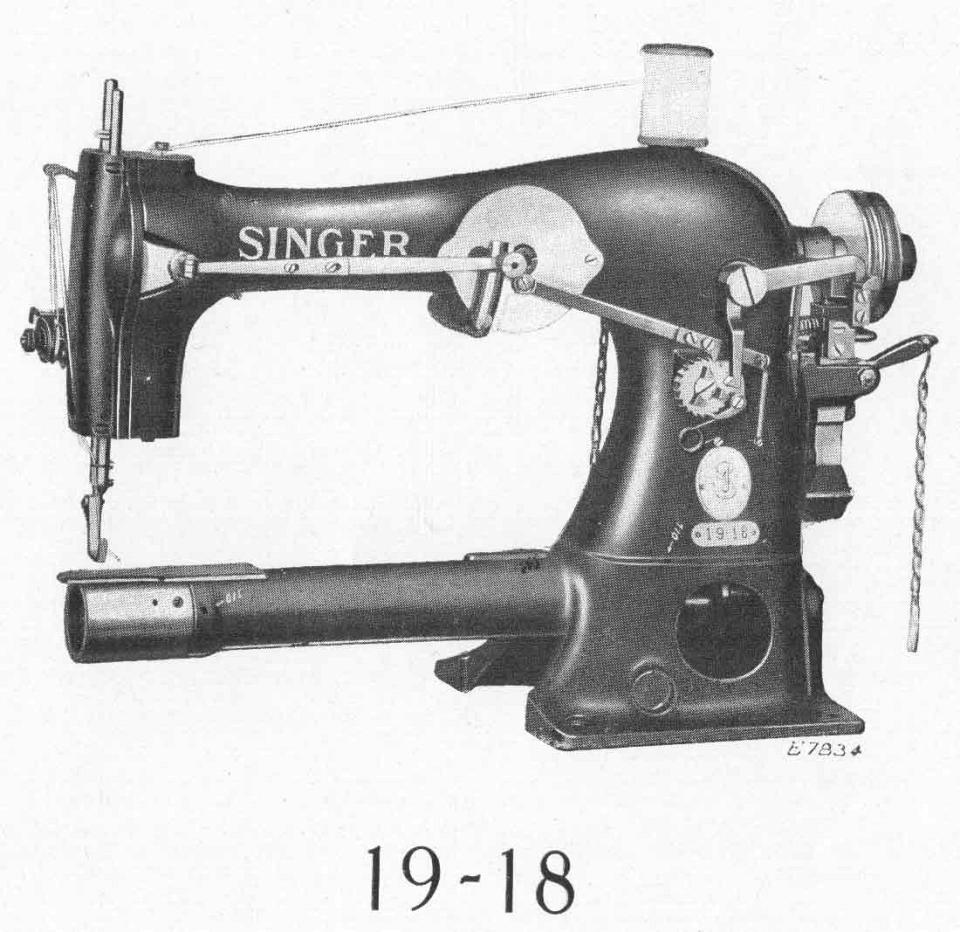

19-18

|

Industrial | Small diameter cy1inder bed- 1 13/16" inches. NO feeding mechanism. Ratchet wheel. Max. 800 C.P.A. For tacking bows, buckles and ornaments on shoes, after lasting. | 31x1 (3027 ) |