If necessity is the mother of invention, the man who "designs shuttles for Singer" could be the father...

A Great Diehl of Invention

The Singer Experimental Division at Elizabethport during the latter half of the nineteenth century must have been a busy place. The company's ceaseless patents - it filed applications more often than people file nails - and myriad solutions to production problems originated in this hotbed of early industrial innovation.

Its staff included Martin Hemleb (who spent 53 years as an inventor for Singer), Leb. Miller, E.B. Allen (inventor of the Class 35 carpet sewer) and Elial Staples (automatic tension release and that little thread guide clamped in with the needle); under the inspired direction of Philip Diehl, who headed the department from 1875 until his death in 1913.

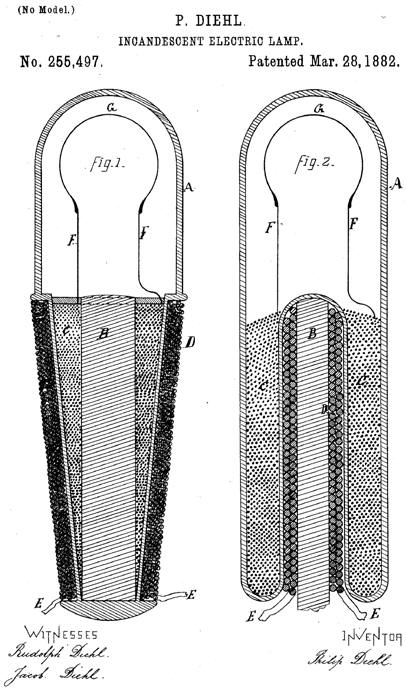

Diehl's ground-breaking induction coil lightbulb, 1882

Lightbulb moment

It is no exaggeration to call Diehl a luminary, as it was his 1882 patent for an incandescent light bulb without 'lead-in wires' (i.e. no connection passed through the glass to compromise the vacuum) that finally released Edison's stranglehold on the market. Five years later, Diehl sold the patent rights to Westinghouse for $25,000. He also invented methods for the first AC electricity supply, arc lights and numerous electric motors, dynamos and controllers, but it's his inventions for Singer that show the breadth of his imagination.

Philip Diehl (one 'l' in Philip - lawyers misspelled it on at least two patents) was born on 29th of January 1847, in Dalsheim; he graduated from the Technical School at Darmstadt and, like Isaac Singer 50 years earlier, emigrated from Germany to the USA. The son of a physician, Diehl had been a locksmith and in 1868, aged 21, became a machinist (engineer) at the Singer factory in Mott Street, NYC.

Two years later, he moved to run Singer's Chicago repair department under James Bolton - inventor of the New Family and the parlour cabinet - who must have recognised an ally in the resourceful young Diehl. His first patent was granted in 1873, for improvements to magic lanterns.

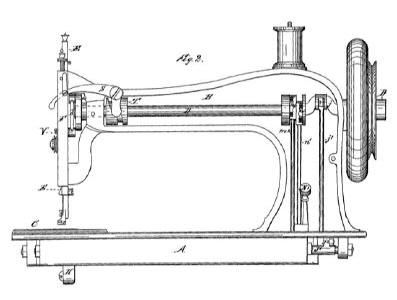

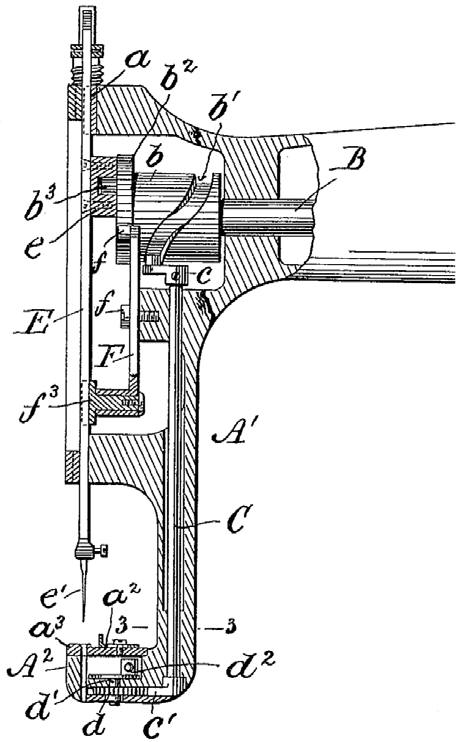

Improved Family (class 15), co-patented with Lebbeus B. Miller, 1878

Bolton was a top salesman who waged a constant battle with the Singer factory - at the most senior level - to maintain the quality and efficiency of its machines. Many were beset with production problems while some, he maintained, just didn't work; forcing him and Diehl to invent an endless stream of improvements and work-arounds in order to have functioning machines to sell.

Inexplicably, many of Bolton's solutions were either ignored or even lost by the company - but examples of Singer's commercial inadequacies abound. The company never bothered, for example, to collect royalties from Goodrich after he'd agreed he'd infringed Singer's tuck-marker patent. Isaac Singer himself was so lacking in vision that he wanted to take a sledge-hammer to the newly invented Model 12. And when they did finally agree to it, Singer's attorney - who'd been on holiday - forgot to apply for the patent.

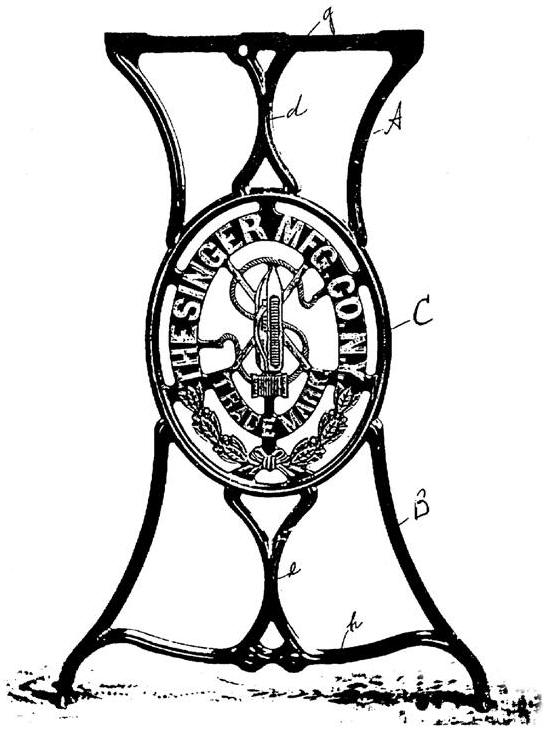

Diehl and Miller's treadle ends were the first to bear the Singer logo

Diehl's home was one of the thousands consumed by the 1871 Chicago fire and he lost everything. It's interesting to note how Bolton proudly announced that, due to the diligence of his staff "working through the night", he managed to save Singer's stock from the flames. One can't help but wonder if the two events are connected.

In 1875, after the opening of the Elizabethport factory, Diehl was summoned - on Bolton's highest recommendation - to take charge of Singer's Experimental Division; later, as Head of Mechanical Construction. One of his first tasks was adapting the No. 4 to sew through inch-thick material for the Philadelphia Centennial Exposition, the following year.

Size matters

The new factory was one of the largest industrial establishments in the world, covering a 50 acre site which had four miles of its own railway in the yard alone. Also, the company was expanding rapidly and would be relying on Elizabethport for all the special tooling and machinery needed to equip the new plants in Canada and Scotland.

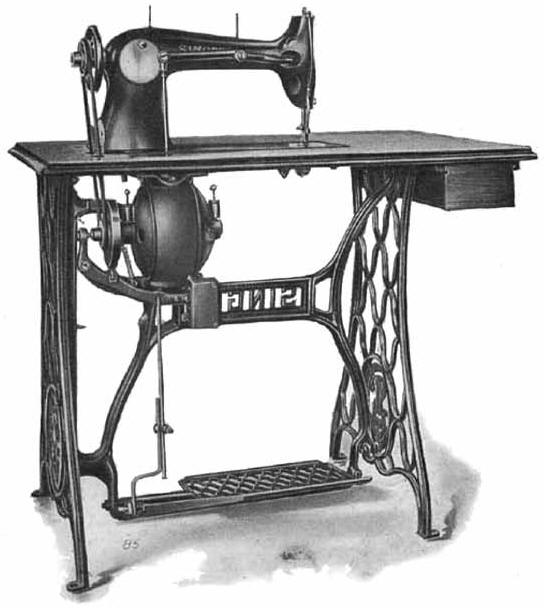

Class 31 on converted treadle with Diehl Manufacturing motor; available in AC or DC (1906)

Singer was a victim of its own success: the more production tried to keep up with galloping sales and an ever-increasing catalogue, the more problems it encountered and the more solutions were needed from Diehl and his staff. Certainly, it is clear that for every 'new' invention they patented, there was another for improvements to existing mechanisms. Diehl held numerous patents for improved minor assemblies and parts. Indeed, in a contemporary report of his most ubiquitous invention, the electric ceiling fan, he was described as the man "who designs shuttles for Singer".

Possibly his greatest contribution to sewing was the Improved Family (later, class 15) machine (1881) - jointly invented with Lebbeus Baldwin Miller - with its oscillating long-beak shuttle (1880); the first to provide even tension and no twisting of the lower thread. It became the best-seller and continued Several of Diehl's patents for Singer were co-awarded to Miller - the works' longsuffering superintendent - who, for twenty years, had valiantly cajoled the factory towards efficient production. Collaboration between the experimental division and the shop floor would have been vital and it's easy to imagine how the two might have pooled their respective skills.

The first electrically powered Singer

Miller had been with Singer since 1863; at the very start of mechanised production there. Though only 30, his experience in small arms manufacturing had been seen as key to the ultimate introduction of 'interchangeable parts'.

Singer's resistance to change was a millstone. Despite its aggressive marketing and mouldbreaking innovations, like hire purchase, it was 'old school' and very conservative. Management - even up to President - tended to groom its successors from within the company, perpetuating old habits and bad practice.

The Improved Family business

And everyone seemed to have a relative on the payroll. Diehl's younger brothers, Rudolph and Jacob both worked at Elizabethport as did his cousin's son, Frederick, who became an equally prodigious inventor with the Diehl companies - the 'Singerlight' was one of his. Diehl's only daughter, Clara Elvira, (b. 1876) married Max Herman Keppler, a Singer executive. Miller's son, Henry, was a mechanical engineer and patent solicitor for Singer; another son, Herbert, was secretary of the Diehl Manuf. Company.

Diehl spent much of 1880-81 trying to design a factory system for the Improved Family (known then as 'the small O.S. model'). It had been proved to be faster, quieter and smoother than previous machines. It stitched better and the bobbins held more thread. Sales were flooding in but Elizabethport couldn't iron out the production.

A continuing problem for Singer was its reluctance to adopt modern armoury practices, with a production line upon which precision-machined components could be simply assembled by semiskilled hands. Instead, the factory stuck rigidly to the 'European' system, where parts were individually engineered to fit a specific machine by skilled fitters and a lot of grinding equipment. This meant that every machine was built by the fitters, then dismantled for the arm and bed casting to be japanned and ornamented, then re-assembled for dispatch.

The only solution was to make parts interchangeable; with each 'gauged' to guarantee uniformity. Finally, in March 1883, the management saw sense and put Diehl in charge of establishing the entire gauging operation. When it came into operation, in the early 1890s, Diehl's monumental system involved over fifteen thousand different no-go gauges.

Hungry for power

By 1880, there had been 75 patents for electrical motors to drive domestic machines but none proved powerful enough to replace a treadle. Eventually, in 1884, Diehl successfully adapted a variable speed D.C. motor he'd recently patented for dentists' drills, and produced the first practical sewing machine motor. On the Singer stand at the International Electrical Exhibition that year, there were "several sewing machines run by various electric motors invented by Mr. Philip Diehl". The first integrated motor was fitted to Diehl's own Improved Family (see picture).

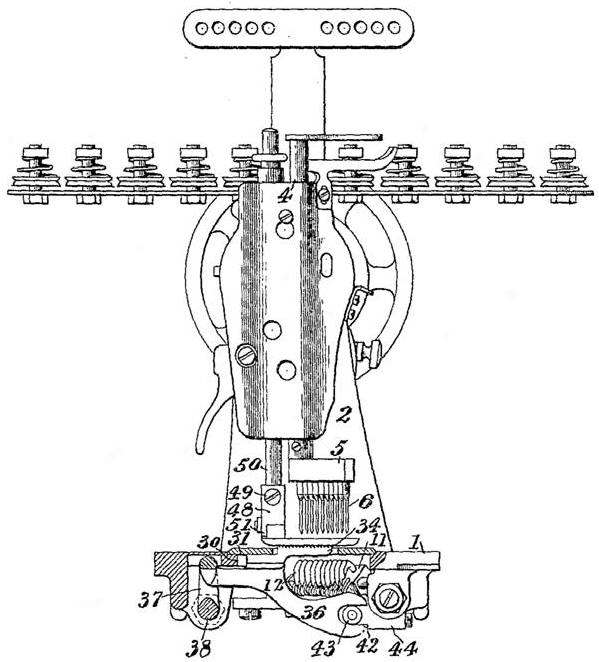

Diehl's 12 needle, 12 thread machine for parallel stitching (1909)

In 1887, in a fit of genius, he bolted blades to this motor, hung it upside down and the ceiling fan was born. That year, Diehl & Company was formed; later incorporated as the Diehl Manufacturing Co.

Ten years later, the Singer catalogue had swollen to 53 different models, comprising 360 different varieties and counting. Sales continued to rise uncontrollably but the factory was now efficient and the boom years had begun - largely due to Diehl and his life-long mission to perfect and create.

In the final years of Philip's life, Diehl Manufacturing Co, needed larger premises but Singer, too, was expanding and commandeered the space at Elizabethport. Diehl moved out; its exports were severely curtailed by WW1 and, in 1918, it was taken over and incorporated as the Diehl Division of Singer. Diehl continued submitting patent applications until the end, with many being granted posthumously. He died in the family home at 528 Morris Avenue, Elizabeth, NJ, on 7th April 1913.

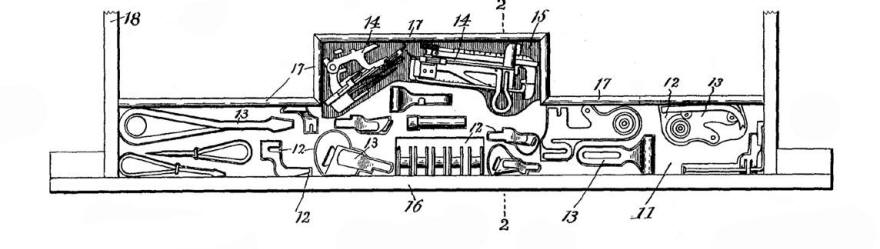

His attachment drawer