Bradbury and the Iron Duke's Machines

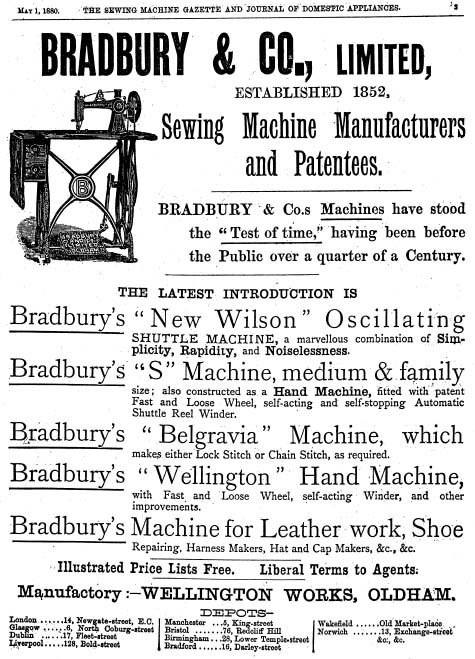

AN INDUSTRIAL dispute led to the formation of one of Britain's largest and most successful sewing-machine manufacturers.

It was in the cruel winter of 1852 that George Francis Bradbury, then 25, found himself caught up in the work-to-rule row at the Platt Brothers engineering company in Oldham, Lancashire.

There was no industrial tribunal, no ACAS. When the workmen started muttering about more wages and less hours, the brothers Platt simply closed the doors of the factory and declared a lock-out.

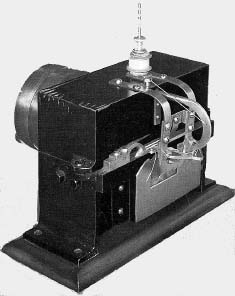

The Judkins patent modelgiven by Platt to theLondon Science Museum

George probably did his share of picket duty and, while standing in the snow, started thinking about the work that the company was losing as a result of the shut down.

Among the orders that should have been processed was one from an enterprising local dealer who had wanted the firm to copy one of the new American sewing machines that were just com

Back in the early days of ISMACS Graham Forsdyke researched and published the histories of a number of famous sewing machine factories. Since that time his archives have grown 20-fold with much new information coming to light.

With this issue we publish the first of a series of updates with much new material, fresh illustrations and the advantages of our present far-superior printing abilities.

Bradbury and a fellow lockout Thomas Sugden approached the dealer, explained that the dispute at Platt's factory was likely to go on for some time yet, and offered to do the job themselves.

1865

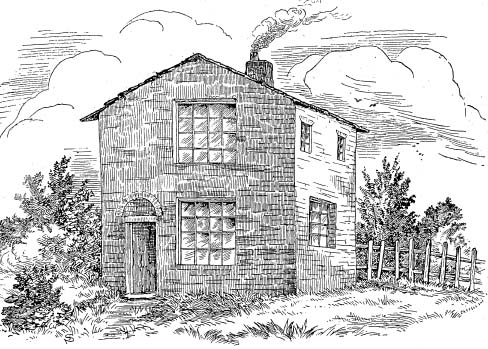

The work was completed in the small cottage at Primrose Bank, Oldham, not far from Bradbury's birthplace his father's inn, the Hanging Gate, at Diggle, Saddleworth, to the west of Oldham.

So small was the "factory" that the steam engine and boiler, which the pair bought for £18, would not fit inside and had to live in a field next to the cottage, with the main drive belt entering through a hole cut in the wall.

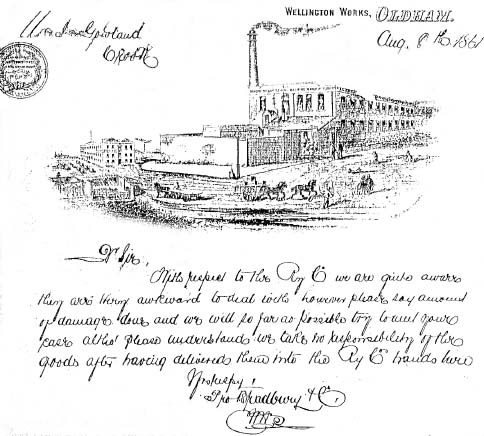

This first machine was produced at a cost of £30. The new company prospered and by 1861, with two patents for folding attachments to his name and an order for 500 machines under his belt, George moved to larger premises at Rhodes Bank where he was able to employ 17 men and six boys.

Little is known of his family, but the 1861 census report shows that he was married to Ellen, some five years his junior, and had two children, Eliza aged two and George Howard aged one. A seven-year-old stepson is also shown, as is a 69-year-old widow, Elizabeth Bradbury, probably his mother.

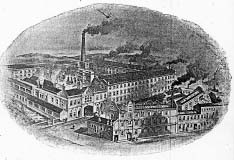

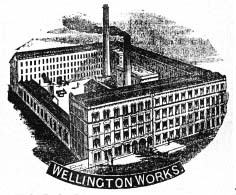

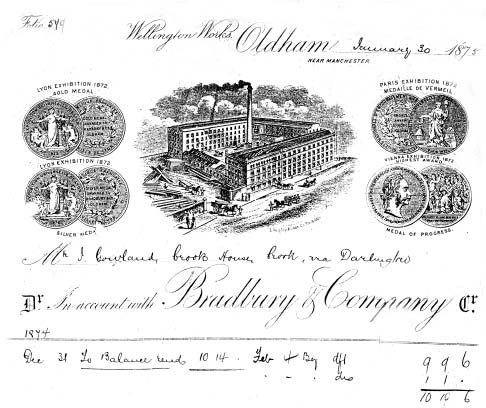

The big gamble came in 1866 when, like many other Victorian manufacturers, the company, which was listed as Sugden, Bradbury & Firth in 1861 but as Bradbury & Co three years later, decided to build its own model factory on Wellington Street, Oldham, and named it Wellington Works.

Where it began in 1852

1908

1920

1883

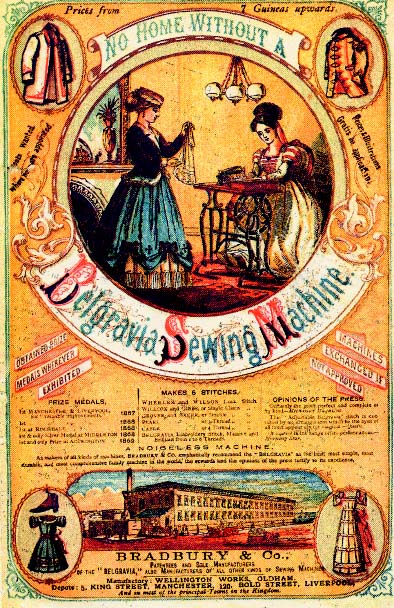

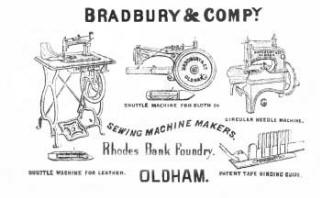

Possibly the earliest use of colour in a sewing machine advertisement. The Bradbury flyer dates from the early 1870s. This plus most other illustrations are from the GF archive

In that year, while the Marquis of Queensbury was drawing up his rules for boxing, Bradbury was enlarging the workforce to fill his new factory. By 1871 he had 244 hands (shortly to increase to over 600) producing more than 25,000 machines a year.

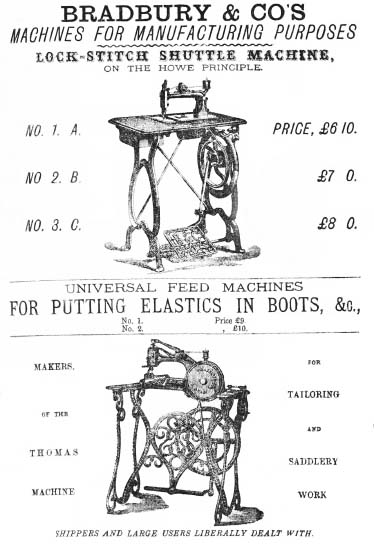

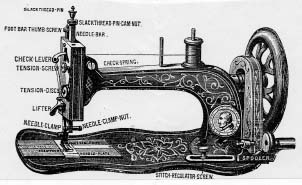

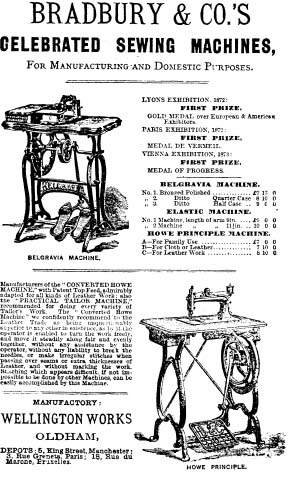

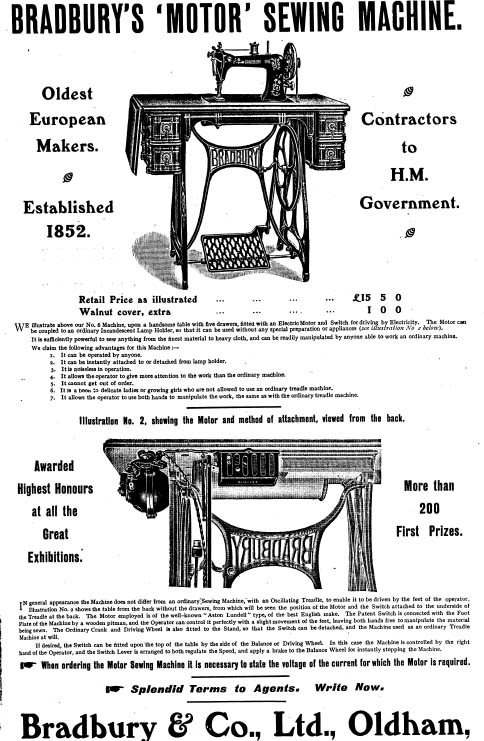

Before moving to the new plant there were three models in the Bradbury catalogue a Thomas-type shuttle machine designed for stitching leather, a Howe-type shuttle model obviously aimed at the home market and a "circular-needle" machine which looked as if it owed quite a lot to early Grover & Baker design.

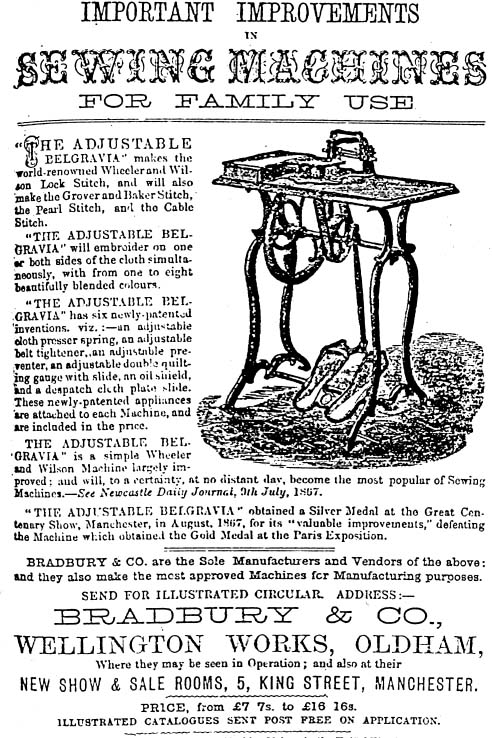

Two years after opening the factory he was advertising an improvement on the old Belgravia machine which he called the Adjustable. This was clearly a Wheeler & Wilson 7 clone, but with several advantages over the American original. These included adjustable-belt tension for use when sewing heavy materials, graduated indictors for presser-foot spring pressure, stitch length and thread tension.

Bradbury also claimed that his machine scored over the W&W in having a quickly-removable needle plate, a dress protector to prevent oil being thrown from the belt onto the clothing of the operator and a lock to trap the flywheel in a stationary position.

As if all that weren't enough, the Belgravia was capable of making six different stitches. They were: lockstitch, double-chain Grover & Baker , embroidery, pearly, cable and, with the aid of a special bobbin, a chainstitch a la Willcox & Gibbs .

The patent for the Belgravia was taken out in 1867 and at once won a silver medal at the Great Centenary Show in Manchester for its "valuable improvements".

1871

By 1869 the Belgravia was being advertised in three forms which differed only in the style of the cover over the machine. The cheapest machine, black-japanned on an unpolished table, sold for £7 7s (£7.35). a polished tabletop and a small lid to cover the machine head hoisted the price to £8 10s (£8.50), whilst the top of the range was the same machine but with a lid completely covering the table at £8 15s (£8.75). It was also possible to have bronzed or even silver-plated arms for slightly extra cost.

The English Woman's Domestic magazine in 1868 reported even more elaborate designs with prices ranging up to a heady £21, presumably for the model referred to by the writer as making "an elegant ornament for a drawing room being fitted with handsome mirrors".

Worrall's directory for 1871, by which time Bradbury had moved to the prestigious Queens Road in Oldham, shows the Belgravia and also the "Howe-principle" machines and also the giant "elastic machine for use in the boot industry".

By 1875 Bradbury, now 48, was on the move again, with a new private address at Crumpsall House to the north of Manchester. This is also the date that his name disappears from the patent applications, although Sugden, H Lomax and T Chadwick, in the company's employ, continued to apply for patents.

It is possible that Bradbury took less interest in the company after this date, for he was to die less than 10 years later and could possibly have retired due to ill health.

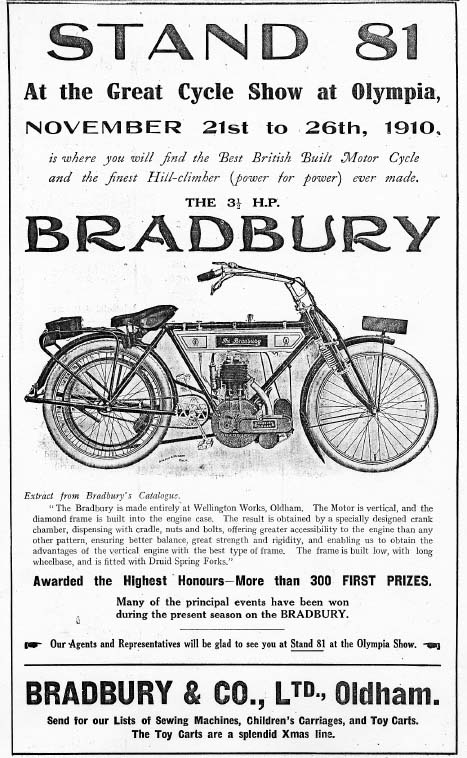

The company continued after his death, producing its first motor cycle in 1898 when there were branches in many big towns all over England and Scotland. It prospered, still in the Wellington Works, up until the 1920s.

But a hoped-for big contract to supply the army during the First World War fell flat and the business eventually folded in 1924, with the factory and its nickel-plating plant the first to be opened in England being sold off by the official receiver.

Around the works

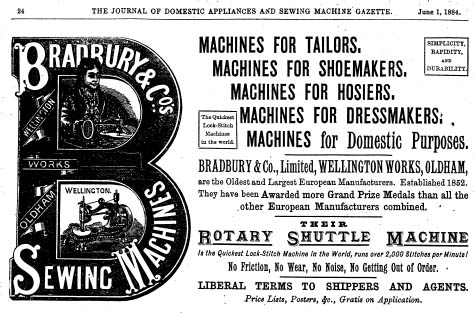

TWO PRESS reports promoting Bradbury, 40 years apart, give interesting insights into engineering and factory practices in Victorian times and just after the First World War, only a year or so before the firm folded in 1924.

We first quote from a March 1882 issue of a weekly magazine: Ben Brierley's Journal, where editor was invited to visit the then-new Wellington Works.

"This extensive concern finds employment for about 480 work people and, incredible as it may now seem, such is the division of labour, that no two people are engaged on the same class of work.

1908

From the fusing of the rough pig iron to the fashioning of a screw so small that we were unable to see the thread, and from the sawing up of logs of American Baywood to the polishing of a cabinet to the most excellent finish, we were permitted to see every process grade by grade until one of the most wonderful pieces of mechanism yet conceived by human ingenuity was perfected and ready for my lady's boudoir.

We were first conducted to an extensive foundry where the earlier stages of the work were being performed. Here we found 25 work people engaged in making moulds and castings; and such is the rapidity of manipulation that we saw one man make a mould in just over two minutes that would cast 42 wheels, each wheel so perfect in its formation that no test whatever need be applied.

The cutting of these wheels is another wonderful branch of the work and so precise in its motion that it would be impossible for a workman to turn out an imperfect piece of work. The polishing of the wheels is on the principle of pebblers on the sea beach - friction. They are placed along with scraps of iron in a barrel which rotates.

The turning, punching and drilling room we found to be a busy hive. Here the largest and most minute parts of a machine were being fashioned; the punch doing the work which would formerly have been done by the lathe - much more quickly and with unerring precision. Such is the variety of work done in this department that Messrs Bradbury need not go outside their own building for any kind of tool used by them."

Possibly the earliest extant letterhead from the Bradbury company

The editor goes on at length about visiting the sawing room where the timber was prepared by 25 hands and explained how the dovetail joints and various mouldings used to decorate the cabinets were produced by new-fangled machines.

Our scribe was further impressed by the production capability of the plant. At the previous factory the limit was a mere two machines Per month, but at Wellington Works 2000 were possible in the same time.

The final visit of our tour was to the inspection bay where the machines were tested.

"One of these was working and making 2,000 stitches per minute. What would your great grandmothers have thought of that?"

1906

Our second report, undated but early 1920s, was a highly-partisan puff piece in the Oldham Commercial Year book as much praising the home town as the Bradbury concern itself that was still operating from a much-enlarged Wellington Works.

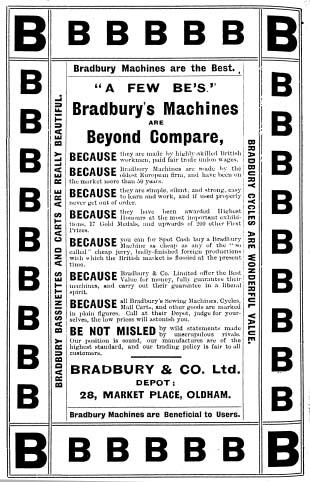

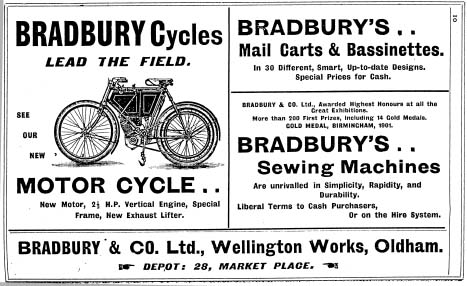

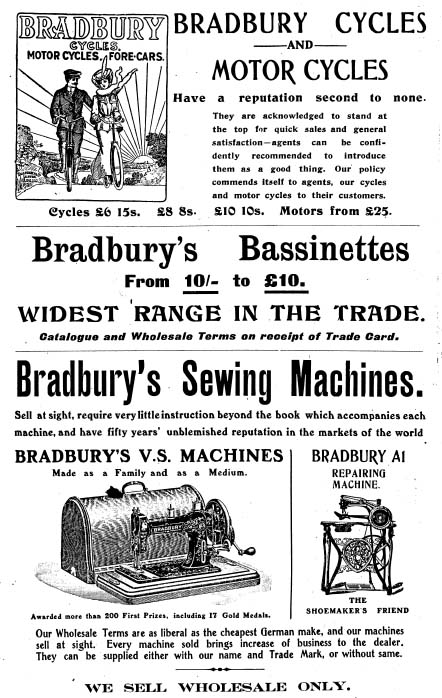

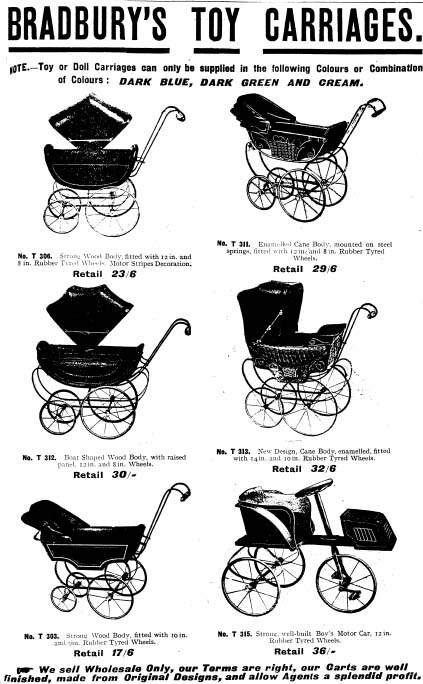

Although Bradbury was still making sewing machines, mainly Singer clones, production had expanded into bicycles and motor-cycles, bassinettes (toy prams) and mail carts.

INDISPUTABLY, it is largely through Messrs Bradbury & Co Ltd of Wellington Works that Oldham is entitled to rank as a town of many industries.

For the most part Oldham devotes herself to the cotton, cotton machine, and textile engineering trades. The versatility displayed at Wellington Works makes her a town at which may be purchased a considerable variety of goods of a mechanical nature.

In this large and well-designed works there are produced articles known the world over for their great worth. Messrs Bradbury & Co's productions are everywhere familiar among the masses as well as the classes in all walks of life.

They are almost universal providers; certainly the variety of goods made suggests that Wellington Works is an engineering emporium.

Some of the goods have a unique celebrity in the privacy of the home, others in the public thoroughfares, and yet others in the furnishings of machine shops and factories.

Concretely stated, Messrs Bradbury & Co Ltd manufacture motor cycles, cycles, sewing machines, machine tools, children's bassinettes and mail carts. All, as you see, are necessities of modern life, as indispensable in war as in peace, in peace as in war.

The motor cycles which used to break records either in the long-distance runs over the variously-surfaced roads very varied; some as smooth as ice, others as choppy as the sea between John o' Groats and Land's End, or in sprints on the even track at Brooklands, gained conspicuous favour as machines of speed, reliability and endurance in the carrying of dispatches, etc, in the several theatres in which the allies fought; the cycles upon which we venture into the sylvan lanes or do business about town or city proved their worth in the nerve-shaking work of the cycle corps; the sewing machines have always been with us bestowing their favours in the home; the machine tools, especially the capstan lathes, were, and are, ready for engineering work of all descriptions where accurate and speedy turning is involved; the bassinettes and mail carts, as before, still convey children reclining in ease and beauty, and making perfect pictures of domestic felicity.

A bird's-eye view

Obviously a business of so great a service to the public is of a most extensive character in its architectural aspect. As will be judged from the Bird's-eye view,

Wellington Works occupies a large area with buildings whose loftiness betokens immensity. They are arranged on a quadrilateral plan around a vast central yard. All the departments are more or less independent of the other, yet so closely and naturally allied as to constitute a perfectly organised whole in which each contributes to the economical working of all the others.

In industrial operations the value of judicious division of labour can be readily understood, but the prudent combination of groups of kindred trades is of quite equal importance in relation to perfect organisation and economical working, and the standard to which both these principles have been brought in the administration of Wellington Works fully justifies their title to their trade mark, "The Duke of Wellington" who was such an unrivalled example of organising and administrative genius in the conduct of great undertakings.

It is this scientific method which enables the company to place their wares on the market at so comparatively low cost. They have little to learn in the way of scientific method. As one moves about the establishment that fact is borne upon one very clearly.

1904

Pioneers of sewing machines

And how did Messrs Bradbury & Co begin? It was first as manufacturers of sewing machines that they became famous. That was the line through which they introduced themselves to the public in 1852, all the other phases of their industry being added as the years rolled on.

In establishing a sewing machine factory, Messrs Bradbury may claim to be pioneers, for they were the first people in Europe to begin making these invaluable domestic implements.

It is interesting to note that the sewing machine was invented by an American serving a term of imprisonment. (Editor's note: Any ideas who this could be?)

A founder of this company immediately foresaw its great prospects, and decided to turn the machines out as fast as possible in England. Such was the demand that it was difficult to cope with it, and wing after wing had to be added to the premises. For a long time Messrs Bradbury remained the only European makers.

Factories have since been established in many places, but, instead of out-rivaling, they have been impressed the public with the greater worth of Bradbury machines, which have always kept pace with the inventive genius of the times without departing from the basic principles which gained for them their initial success in the homes of England and all over the world.

1904

If a Bradbury sewing machine adorns (for an adornment it really is) one's house, one may definitely assert that one has the most rapid, efficient, and reliable instrument for the making or repairing of garments obtainable in the world, and at a price which is remarkably low.

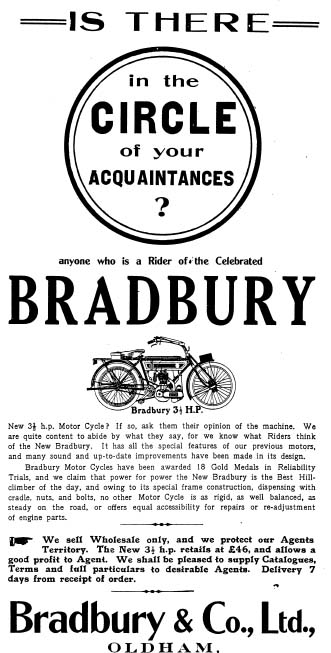

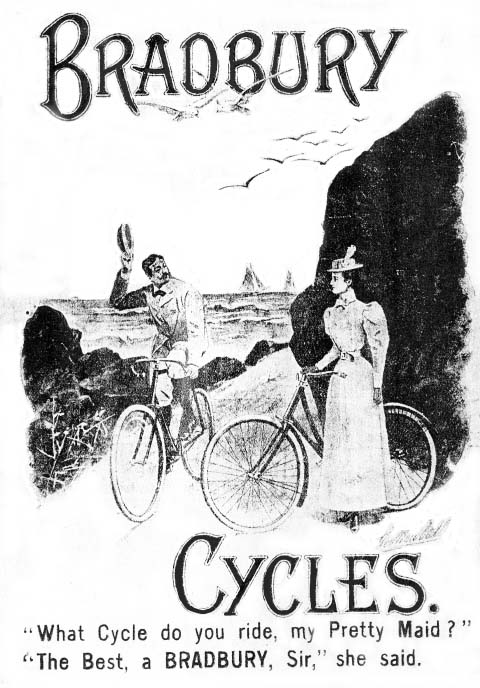

From sewing machines to cycles and motor cycles. The industrial affinity between the manufacture of cycles and sewing machines is obvious, for both depend upon the finest character of light engineering in which perfect accuracy of judgment, combined with the highest standard of strength, rigidity, and lightness, are the essential desiderata; hence the Bradbury cycles and motor cycles eventually, and, indeed, inevitably made their appearance at Wellington Works. One, as it were, grew from the other; first came sewing machines, then cycles, and, next, motor cycles.

An illustration hereabouts shows one of the several types of cycles made. Known as the "Gent's Special" it has elegance, gracefulness, finish of design, and a capacity for endurance which are unrivalled. Its very appearance thrills one and makes one long to mount it and hasten into the fresh atmosphere of the country at a speed which is pleasant and invigorating.

The "Gent's Special" is of distinguished bearing; it is the Beau Brummel of the cycle world, though fit for more hazardous adventures than the Bond Street dilettante.

1899

A credit in Kensington, it is also supreme on the rough colonial and foreign roads, its gentlemanly qualities being adaptable to all conditions..... (etc, etc.)

Exceptionally great attention is devoted by Messrs Bradbury & Co Ltd to the manufacture of motor cycles and side-cars, which is a comparatively new industry and has possibilities of great development.

The advantages appertaining to the ownership of a motor cycle need not be dilated upon; they are so obvious. But the advantages accruing from a Bradbury motor cycle not always found in other machines and there are now many competitors may be spoken of, although to owners those advantages too, are obvious.

Machines of varying power are needed, from the singe cylinder to the 6hp three-speed twin, although there are three main types the 4hp single cylinder, the 6hp V type twin cylinder and the 2.3/4hp "Lightweight. These three main types differ very widely from each other, for the simple reason that each has been specially built to give the very best results for its own particular purpose; each, in fact, represents a highly-specialised machine.

But while each main type is entirely different from the other, the advantages of standardisation have been fully realised, and, as far as possible, the details in all machines have been kept unaltered wherever this could be done without sacrificing efficiency.

Thus, up to a point, the details of one machine could, if necessary, be fitted to any other; in fact, by the use of automatic machinery standardization has been carried to a very high pitch in the Bradbury machines, but only so far as in no way to interfere with the efficiency of the machine as a whole. If in any type it has been found that a specially-designed detail would give better results than the corresponding existing part, then there has never been any question about it neither is standardisation allowed to interfere with efficiency.

1895

Efficiency makes the pace

As to how this efficiency has been attained results speak eloquently. Take, for instance, the Irish end-to-end record held by Bradbury. It was in 1911 that a 3.1/2hp Bradbury chain-drive motor cycle and side-car created a sensation in the motoring world by completing the journey of 390 miles in 14 hours and 9.1/2 minutes; and in 1912 it covered the journey of 886 miles from John o' Groats to Land's End in 38 hours 47 minutes.

Towards the close of the same year at Brooklands it established the following unprecedented times: 50 miles in 1 hour, 5 minutes, 47.4/5 seconds = 45,59 miles per hour; 100 miles in 2 hours 10 minutes, 19 seconds = 46.04 miles per hour; the One-hour Record, 45.44 miles; and the Two-hours' Record of 91 miles, 1,752 years = 45.99 per hour.

It was a 3.1/2 Bradbury which won the Transvaal championship in 1912 and 1913, in the latter event 3.1/2 miles of rough and hilly South African road with many abrupt turnings being ridden over at an average of more than 60 miles an hour.

It is records like these and many others which have convinced the public of the superiority of Bradbury motor cycles, and created so great a demand that the makers can hardly keep place with the orders.

The extension of plant, however, is enabling more deliveries to be made. Messrs Bradbury is just now introducing to the public a new light-weight motor cycle with a 2.3/4hp four-stroke engine. It is a beauty, and the severe trial runs to which it has been subjected and come through with flying colours afford the makers every assurance of almost a sensational success.

Peace will have been with us but a short time before these machines are scampering about in scores delighting their owners.

1871

A tour round the works

Merely remarking that the offices are spacious and have a good presence, one enters the works, and the first impression of everything being well ordered and carried out scientifically maintains itself to the end.

Better ventilated and more comfortable "shops" than these one has not seen in the course of a long tour of industrial establishments.

Everywhere there is a neatness and a spick-and-span look about things that make one say, "No wonder the products of these works are spick-and-span, too!"

All the machinery is electrically driven, and a pleasant tone pervades the whole works. So huge is the works that one must speak generally, more or less, if all the ground is to be covered.

George Bradbury's birthplacethe Hanging Gate Inn at Diggle

One cannot expatiate in detail upon the costly and elaborate equipments, the endless variety of ingenious labour-saving machines and appliances, and the well-ordered industrial activity to be witnessed in the nine splendid machine shops the forge and foundry, the moulding, stamping, fettling and turning shops, the frame shops, and the glazing, enameling, plating, assembling, and finishing shops, with all the subsidiary departments, such as the cabinet and wood-working shops, etc, all of which have their own special staffs of experts working with unremitting care, industry, and skill, under experienced and responsible supervision.

1880

Moulding and casting

The basis of nearly everything mechanical is created in the foundry and moulding shops, and those at Wellington Works are interesting either as regards general appearance equipment, or the work upon which the employees are engaged.

In a large building of three bays, each about 50x10 yards, these shops are lofty and well-lighted at night by electricity and are admirably equipped for the production of the various light castings required.

There is no need for Messrs Bradbury to buy any foreign castings; they make all their own, and, what is more, sell a considerable quantity. All the cylinders are cast from brass patterns the plate and plaster system-which, while reducing manual skilled labour to a minimum, enables the castings to be turned out with great rapidity, precision, and economy.

In close proximity to the foundry are the dressing and fettling shops, near by which a dozen rumblers are at work-making a noise like an artillery bombardment-ridding the castings of the sand.

For expunging the sand from the cylinders, whose delicate tracery requires exceptional care, a man enters a huge safe-a kind of "pill box"-and, attired like a diver, sand-blasts them.

Enamelling and grinding

1904

A prominent feature of the ground floor is also the enamelling department, the operation being to dip the articles in vats and then place them in gas stoves for several hours-a process which hardens the enamel to the greatest degree.

For motor cycles the process of dipping and hardening is gone through five times. By this means a finish, not obtainable by any other means, is achieved. A layer of varnish makes an adequate protection for the highly-polished enamel.

The grinding shop is in close proximity, and here again nothing but the best and latest machinery is in use. Special automatic internal grinders, with vacuum scavengers, are employed for the cylinders; Churchill's famous grinding machine (with magnetic chuck) deals with piston-rings and similar operations, and two splendid Universal" machines complete the group, and form a department of which the firm is justly proud.

Specialists in lathe making

Light and airy machine tool fitting and turning shops have a commanding position. It is here that the machine tools are made, the capstan "lathes" being particularly in evidence.

It may be mentioned that these famous lathes have a capacity of from 1/2in. to 2in. i.e. they can take a bar of from 1/2in. to 2in. for tuning purposes.

Messrs Bradbury specialise in lathe-making. The many machines adorning their establishment were all made by themselves. Lately developments have taken place in the manufacture of automatic lathes, and Messrs Bradbury are to the fore with their variety of labour-saving machinery. On the same floor are the Planing and Milling Departments.

Fitting of sewing machines of several types

Perhaps the largest room in the works is the sewing machine fitting department on the first floor. The castings have been made, drilled, and turned below, they are elevated to this department where they are completed. In a room adjoining, each machine is tested by thoroughly experienced women who understand the merits of the machinery and their possibilities for dressmaking, etc.

It is the practical test which every machine is subjected to here which guarantees that the sewing machines are ready for service.

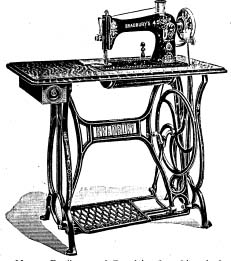

It may be added that several classes of sewing machines are manufactured, from the portable and handy handle-turning variety and the treadle machine which, by reason of its artistic design and workmanship, forms a beautiful and useful piece of house furniture to the factory machine for clothing and general heavy work, and an elastic machine suitable for the leather trade.

When being tested, the machines are worked by electrical power so that a great speed can be attained, thus enabling their durability to be judged.

The packing and dispatching departments are on the same floor, and there is quite a busy and exciting scene as the machines are lowered through the "loading holes" to the railway lorries below.

1864

Small turning

The work on the second floor is equally interesting. Occupying one portion is what is known as the "small-turning" department, where the lightest parts of the sewing machines, motor cycles and cycles are made.

To the right, the carpenters busy themselves making the cabinets for the sewing machines it is an interesting fact that the wood arrives in logs-and to the left the French polishers are at work, giving an artistic finish to the labours of the carpenters.

Forging and stamping

1909

On the ground floor also are the forge, stamping, and punching departments. The forge has as many as nine open hearths. There are many stamping and shaping machines and various portions of the sewing machines and of the motor cycles, such as lugs, fork-ends, cam-wheels, valves, gear- wheels, etc, are to be seen being stamped out of the best steel at almost every hour of the day.

Motor cycle fitting

Stationed on the third floor, the motor cycle fitting department occupies a considerable area. It is here that the wheels are built, quite a considerable number of hands being engaged in cutting and screwing the spokes and fitting same to hubs and rims; a specially thick gauge of wire is used for the wheels, thus obviating spoke trouble.

The Bradbury wheels, as now constituted, appear to be regular "Dreadnoughts" and stand the racket of rough colonial roads exceptionally well.

The rooms on this floor are literally packed with wheels, forks, frames, gears, and handlebars all made on the lower floors, excepting the wheels-and these are assembled in scientific manner so as to be turned out speedily and efficiently.

As soon as they are got together, the motor cycles and cycles are subjected to an adequately searching test, so that customers always obtain reliable goods.

The steel works

1908

That is just one part of the works touched upon ever so broadly. Across the street is another large building. This may be regarded for the most part as the steel works.

In several enclosed areas lie tons and tons of steel bars and tubes, and nearby stands the smithy.

As the foundry is to cast iron, so the smithy is to steel, and here may be observed workmen hammering away at white-hot steel bars with diameters of anything from a small part of an inch to 4.1/2 inches, the small sizes being for the sewing machines and the larger for the lathes.

The hardening section is a most important branch, for it is here that the steel is hardened for the parts of the cycles, sewing machines, and lathes which require to be of toughest fibre because of the great strain they will have to bear when being used.

For the purpose of hardening, Messrs Bradbury have an up-to-date plant, and, by means of the six pyrometers at hand, can tell to an infinitesimal part of a degree the heat in vogue. The process of hardening is extremely interesting in all its details.

Bassinettes and toy motor cars

Thomas Chadwick

On the next floor is the main mail cart and perambulator department, every portion of whose productions are made by Messrs Bradbury, excepting the rubber tyres.

It is in this section that the side-cars for the motor cycles are fashioned, as also are the toy motor-cars for boys and bassinettes for girls the possessors of larger ones in after years!

The painting and finishing of these goods takes place on a higher floor, this also being a convenient place for the picturesque and comfortable upholstering to be done.

A hurried glance through a large works making such a variety of goods, one might say; but enough has been said to impress readers with the stability, usefulness, and pre-eminence of Messrs Bradbury & co Ltd, not only in Oldham, but among their competitors throughout the world.

Chadwick: Bradbury's Right Hand Man

Perhaps with tongue in cheek, the Bradbury Family was said by theTrade papers to "be somewhat similar in appearance to the Singer . One "improvement" was a much larger shuttle

ANOTHER youngster from the Platt Brothers company played a large part in the Bradbury story.

Thomas Chadwick started his working life as an apprentice with Platt's in Oldham in 1860, working his way up to become a fully-accredited mechanic. But he decided that he could do a better job of running the business and purchased the shares of each partner until he owned the business outright.

He then cast around for another partner and settled on William Jones , who was later to form his own company at Guide Bridge, near Manchester. This short-lived partnership lasted until only 1864 when Chadwick was tempted away to join Bradbury, later to become the firm's joint managing director.

Chadwick, a local council alderman, died in 1886 aged 56, at which time, after the death of Bradbury, he was chairman and managing director of the business. He too was the owner of many patents, some taken out jointly with Bradbury and/or Sugden.

Thomas Sugden himself was officially titled an "improver and inventor" at the Bradbury plant. He was still employed by the company when he died, aged 72, in 1888. Initially, both he and his brother Frederick left Platt's to work with Bradbury, but of Frederick no more is known.

A newspaper report at the time of his death states that he (Sugden) and Chadwick became the proprietors of the Bradbury company at a date not given. But as the same report gave Sugden credit for inventing the Lancashire sewing machine, this might not be the most reliable source.

We include some excerpts from an interesting Press report from 1885, a year before Chadwick's death, that gives some insight into his place in sewing-machine history and also some information gleaned from obituaries.

1902

1909

Interesting presentation at Oldham

On Saturday evening an interesting presentation was made to Alderman Chadwick by the employees of Messrs Bradbury & Co Ltd to testify their gratitude at the high respect and esteem in which he has ever been held by them during the 21 years he had been connected with the firm.

The event is the outcome of a spontaneous effort in which all the workpeople have taken part by contributing their quota to the presentation fund.

The presentation by general consent took the form of a life-size portrait of Alderman Chadwick, and a beautifully illuminated and artistically designed address.

The portrait, which is a faithful counterfeit presentment of Mr. Chadwick is painted in oil, with massive frame, and has been most admirably executed in every detail and with artistic finish by Mr. W H Johnstone, artist, of Manchester.

It bears at the bottom the following inscription:-

Presented to T Chadwick, Esq., by the employees of Messrs Bradbury and Company, Limited, March 14th, 1885. The address which is an excellent work of art executed on vellum, is the work of Mr. Albert Thomas of Oldham.

Mr. Thomas Sugden presented the portrait and referred in complimentary terms to Mr. Chadwick's long connection with the firm, and to his kind and courteous bearing towards all the employees of the firm.

Saturday's proceedings were commenced by a substantial tea, at which about 500 sat down, the gathering consisting of the employees, their wives, and a few friends.

Though Chadwick attended with his wife and daughter, he was too ill to make a speech so it was read out on his behalf.

He thanked "those of you who are employed at Wellington Works and I would offer my best and most sincere thanks for this manifestation of your kind feelings cheers sympathy, and goodwill towards one who has for last 21 years renewed cheers been connected with the firm of Bradbury and Company and Bradbury and Company Limited, 10 years as a private employer along with the late Mr. Bradbury, and 11 years as a managing director of the present company.

There are a few now present who worked for the firm on my first joining it in 1864, at Rhodes Bank.

The number of machines made in the year 1863 previous to my joining the firm, was about equal to one week's production at the present time. It was in 1866 we commenced to build the first installment of Wellington Works. The years from 1868 to 1874 were years of great prosperity to the private firm.

The rapid increase in the business necessitated increased capital, so that early in 1874 the private firm disposed of their entire works and business to the present limited company, myself and the late Mr. Bradbury being appointed managing directors, which post I continued to hold at the present time........

1884

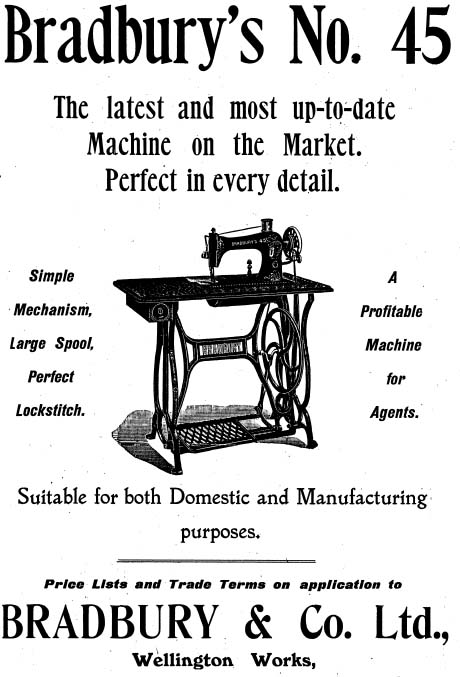

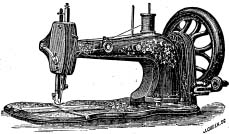

In 1906 Bradbury introduced its No 45 model which was actually the 45th different machine to be produced by that date. It was slightly larger than the usual domestic model, being aimed at serious dressmaking and light industrial use. The company claimed that it made a "firm and pretty lockstitch at a high rate of speed"

I first entered the business of sewing machine manufacturing in 1860, along with a few others, in a small way at Werneth, they having previously been engaged by a local firm in the making of sewing machines.

I soon discovered they had but little knowledge of the trade which they had entered into. I at once took steps to disengage myself from them. This I did by purchasing the shares of each partner respectively till I was left alone.

At this juncture I took in partnership Mr. William Jones , now of the firm of Jones & Co, Guide Bridge. It was agreed to leave Oldham and establish ourselves at Ashton-under-Lyne, in the name of Chadwick and Jones .

This partnership came to an end, after which I joined the late Mr. Bradbury in January, 1864. About this period the trade was beset with great difficulties, in consequence of legal proceedings by rival patentees.

During that or the following year all persons known to be either making, selling, or using sewing machines in Great Britain were served with "writs of injunction" pending the decisions in the law courts of the various actions which were then going on.

After these trials things settled down, and business began to grow in this and other countries.

A fine example of the Bradbury Belgraviain the London Sewing Machine Museum

The first establishment for the making of sewing machines in Europe was started in an outhouse or small cottage at Primrose Bank, in Oldham, by our old and esteemed friend Mr. Sugdencheersin partnership with his brother and the late Mr. Bradbury.

They had, therefore, earned for Oldham the distinction of being the birthplace of sewing machine industry in this country and Europe.

As the promoters of a branch of industry which has called mechanical art into its service, and produced a machine that has proved itself a blessing to households of the world, and provided employment for large numbers of artisans and workpeople of both sexes,

I am proud to say we have the largest works of its kind and employ more hands than any other firm in England-(cheers)-and also make more machines yearly than any other company, our goods being known all over the civilised world........."

Not the prettiest machine, but a rareexample of the Bradbury rotary model

The portrait and address were exhibited in front of the platform around which was displayed a choice assortment of plants. During the evening a pleasing entertainment was given.

In 1884 Chadwick suffered a severe stroke and never returned to normal health. He made occasional appearances at the Wellington Works but by the end of 1885 was too ill to continue to manage the company and effectively retired, dieing one year later.

Chadwick was in the words of the time the "architect of his own fortune". He was born in humble circumstances and was orphaned when only six years old.

The young Thomas was adopted by an uncle and aunt but such were there circumstances that he only received a very elementary education.

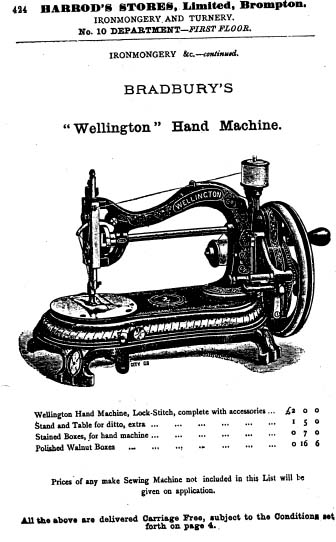

Most common found of the handcranks,the Wellington model

He rose to manage the mighty Bradbury concern and also took an active interest in politics, being an alderman of Oldham Town Council. His politics were Liberal and his religion non-conformist.

Flags were flown at half mast in all municipal buildings on the day of his funeral where the horse-drawn funeral hearse was followed on foot by a number of the longest-serving Bradbury staff.

The Machines Today

WHEN Bradbury and Sugden took over the Platt Brothers order they set out to produce a clone of the Grover & Baker that Charles Judkins brought over from the USA. As far as I know only one of these has survived and is currently in store at Clydebank.

Advertisements in the early 1860s show this machine, a Howe clone, a Thomas clone and a patented binding guide. It is not until the later part of the decade that the Belgravia, first labeled the "Adjustable" and then the "Improved", appeared.

The Grover & Baker "Lancashire" machine had quite a long life as an industrial model and I'd not be surprised if others eventually surfaced

The Judkins machine which was exhibited at the Great Exhibition in 1851 was made by Platt Brothers who, in 1909, presented a replica to the Science Museum. Obviously, if Judkins were using the Platt company in '51, it would have been an obvious choice a year later also. And it would have been this" Lancashire" design that the locked-out strikers turned entrepreneurs made in their back shed.

It was an instant success and was, according to the Newcastle Daily Journal in July of 1868: "destined to become to most popular of all sewing machines".

It would seem that the company saw the Belgravia as a domestic-market machine only, for this was the model pushed in advertisements as ideal for home use. Although also offered for the home market, the Howe-based machine was also vaunted as ideal for manufacturing purposes and, of course, the Thomas-inspired monster was purely for industrial use in the tailoring and saddlery industries.

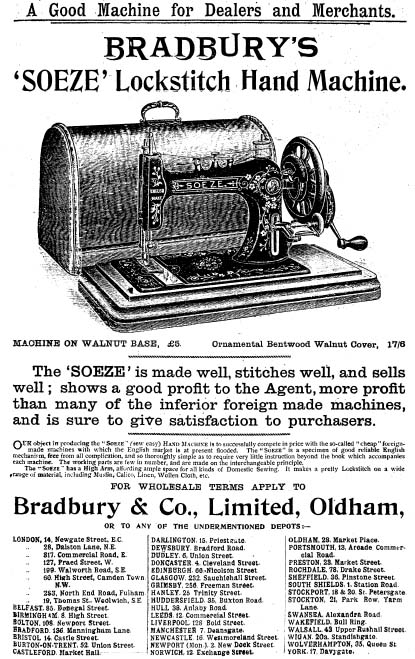

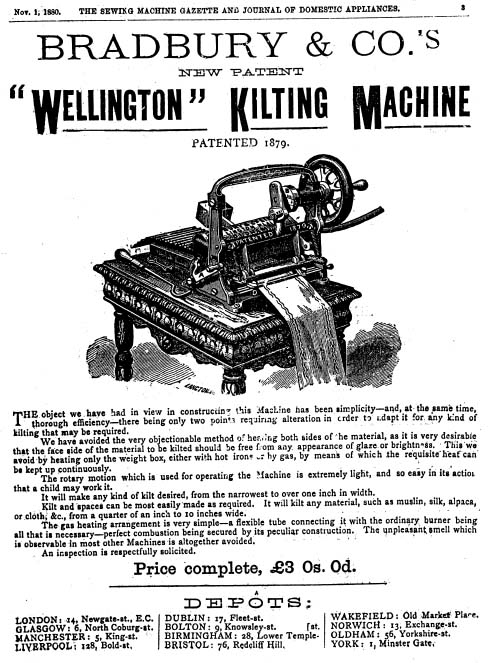

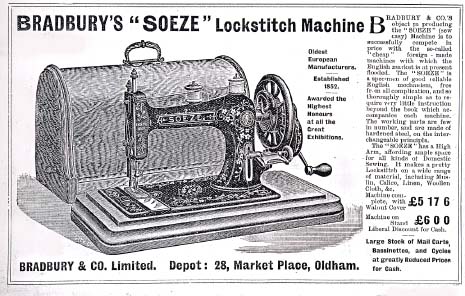

Later machines to emanate from Wellington works included the Wellington itself one of the few hand models from a company which seemed to devote most of its production to treadles the company's own Rotary-shuttle of conventional late-19th century appearance, and the Soeze.

So the Grover clone must be the ultimate find today followed by the Belgravia in the mirrored cabinet or in a Davonport desk.. There are a goodly number of these in collections and it's quite possible that there are more just waiting to be found.

The Wellington hand machine is common enough to make it worthwhile only seeking out a really good-quality example.

The range in 1875

Wheeler & Wilson inspired

The Journal of Domestic Appliances published an article1875 which included a list of the wide range of machines the Bradbury company was producing at that time.

Messrs Bradbury & Co manufacture a greater variety of machines than almost any other house.

They commenced operations by producing the "Lancashire" which is still very much in demand for heavy work, but the machine which has helped more than any other to give them their world-wide reputation is the "Belgravia" a gem of a machine on the Wheeler & Wilson principle.

This machine has been in the market upwards of seven years and is now so well known that any description of it would be superfluous.

It has several patented improvements, such as the adjustable cloth presser, the moveable presser foot, the Archimedean feeder and some half-dozen others, that render it one of the most perfect and complete machines of its class, the Belgravia being as its name indicates quite a ladies' machine is produced in a variety of ornamental cabinets, some of which are of very choice and artistic design.

Another and quite distinct class of machines are those known as their letter H, which are made on the Howe principle, and are supplied either with the step or the wheel feed-the former being used for cloth, and the latter for leather work.

They also manufacture an elastic Machine for stitching new elastics into old boots, restitching the goloshes, or front and back straps, stitching patches on, and for doing all manner of repairs whilst the old soles are on.

It can be used for flowering and will do ordinary boot closing as well, and is one of the most useful of its class and one that will soon repay its cost to any boot maker.

One of the latest novelties produced by the Company is their improved Letter 8 machine, with new patent fast and loose wheel, which the company claim to be one of the greatest improvements effected in sewing machines for a long time past.

Among the advantages of this machine is the following:-

It saves 25 per cent in the wear and tear of the machine.

It saves the necessity of unthreading the needle or removing the sewing.

It entirely prevents the machine from working the wrong way.

It is perfectly noiseless.

It requires no change of regulation of any kind, and lastly

It cannot possibly get out of order.

Howe inspired

Singer inspired

Breaking of cog wheels is also prevented by the automatic shuttle cover, which prevents the shuttle leaving its position whilst working a troublesome occurrence so common in this class of machine. Each machine is fitted up with these improvements free of extra charge.

Besides these, they also produce the Letter T, the Practical Tailor, and the Universal Feed, all of which are highly valued for manufacturing purposes.

The Government Commissioners' Report on machine Tools, Textile and other Machinery (group xiii) at the Vienna Universal Exhibition of 1870; published and presented to both Houses of Parliament by command of her Majesty, contains the following:-

"In the display of Sewing Machines, as a whole, we have great reason to be well satisfied, more especially with that of Bradbury & Co of Oldham, which was indeed superb, alike in regard to real goodness, novelty, and variety, both for domestic and manufacturing purposes, and probably there were none better in the Exhibition.

This is saying a great deal when it is considered that the display from most countries were characterised b a very high standard of excellence.

The amount of ingenuity, which has been brought to bear on the Sewing Machine, in order to simplify the details, to render it more convenient, to reduce the friction, the noise, and the cost, yet without losing the essential conditions, is indeed marvelous, and can only be appreciated by those who have had to examine them by the hundred."

Messrs Bradbury & Co's Machines were made in different ways, some on the well-known "Howe" system, combined with certain modifications.

They had some Machines with a more elastic construction of mechanism that seemed to make beautiful stitching, and the greater number of the Machines were furnished with the little appliances for hemming, braiding, and other such like purposes."

This is very high praise, but it seems to me to be fairly deserved.

I noticed that the instruction books of the Company are translated into Russian, French, German, Spanish, Portuguese, Italian, Norwegian and Welsh, and Bradbury and Company have established an enormous export trade to all parts of the world.