How a Sewing Machine Forms Stitches

This page compliments of Sharon Reese

From the definition of "sewing machine" found in "Nelson's Perpetual Loose-Leaf Encyclopaedia" dated 1917.

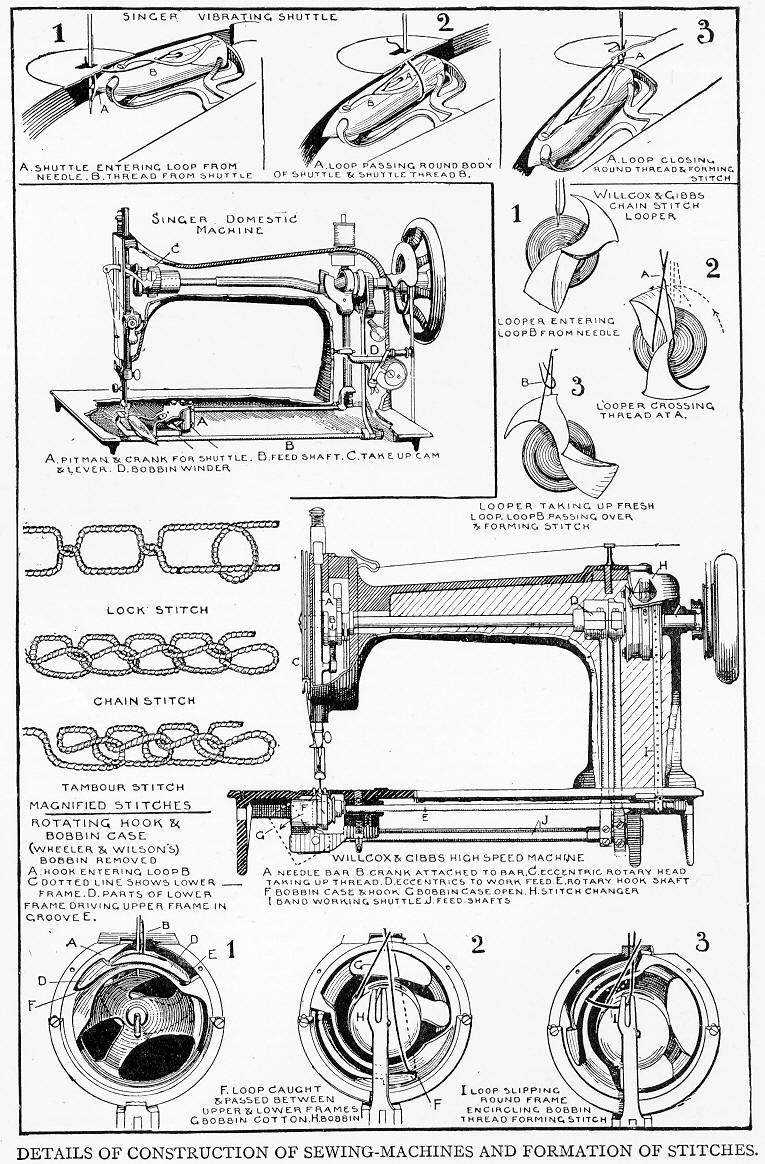

See text below picture.

(The following text is one long paragraph in the encyclopedia. I split it up for ease of reading. Please note: The word "unraveled" is spelled "unravelled" because that is how it appears in the encyclopedia.)

Sewing machines are of two classes - those for domestic use, usually driven by treadle or hand, and machines of special construction, driven by power, for use in the various industries. The principle upon which the machine works is the same as in all types: the needle is clamped to a bar or arm which moves vertically up and down at great speed, piercing the material to be stitched, which is placed upon a flat or curved steel plate. The needle is made with the eye near the point, the eye passing through the material, which is moved automatically for a small distance at a time, to form the stitch. Two kinds of stitches are chiefly in use--the single-thread or chain stitch, which can be unravelled by pulling the end of the thread, and the double-thread or lock stitch, in which an upper and lower thread are used, locking together in the centre of the material; this stitch cannot be unravelled, but must be cut through if the material is to be taken apart.

The operation of the chain-stitch machine is as follows: The needle descends through the material and throws out a loop of thread, which is seized underneath and held by a hook-shaped piece of steel called a looper, which has a vibrating or rotating movement. The needle then rises, and as soon as it is clear of the material this is moved forward the given length of the stitch. The looper then spreads the loop of thread across the path of the needle; this descends again through the loop, which slips off the looper and is drawn tightly up to the under side of the material. The needle next throws out a new loop, which is seized by the looper, and the operation proceeds as before. The appearance of the stitch is as a straight line on the upper surface, and as a series of interlocked loops on the under side.

The operation of the lock-stitch machine is as follows: The needle descends and throws out a loop as before; through the loop a second thread is passed by a vibrating shuttle, or the loop is passed over the under spool of thread by a steel circular hook having a rotating movement. When the needle rises, the second thread is drawn tightly up to the under side of the material, and the two threads interlock together in the centre. To facilitate the formation of the loop, and to permit the under thread to be passed through it, the needle is made to pause for an instant, and descend again in the up-stroke just after is has commenced to rise. The upper thread, after leaving the spool, which is carried as a pin fixed to the upper part of the machine, is passed between steel plates pressed together by an adjustable spring. The arrangement is termed the tension, and its object is to put a strain upon the thread, and consequently determine the tightness of the stitch; it then passes through a slot or hole in the upper end of the needle-bar to the eye of the needle. The stitch is drawn tight by the rising of the needle; and, as the thread would be left slack on the downward movement, a vibrating arm is provided, termed the automatic take-up, which engages the thread and draws it tight, releasing it at the moment of formation of the loop and at the end of the needle up-stroke. The lower thread is wound on a bobbin carried within the shuttle or rotating hook, and also provided with tension arrangement.

The material is kept from rising with the needle by the presser foot, a forked plate of steel carried at the end of a bar parallel with the needle-bar, and pressed down by a spring which is adjustable. The material is carried forward during the stitching operation by a small toothed bar or 'feed-dog,' which rises through a slot in the cloth plate underneath the presser foot, engages with the cloth, forces it forward the length of the stitch, then falls below the cloth plate, and moving back rises again and repeats the operation. With lock-stitch machines the stitch should have the same appearance on both sides of the cloth. Various attachments are provided for hemming, cording, braiding, ruffling, tucking, quilting, embroidering and tambour work can also be executed.