Early French Electric Sewing Machines

Martin Gregory

ISMACS News

Issue 61

THE FIRST central stations to supply electricity to the general public were in 1882 in London and New York. For the domestic user the alternative was a collection of "wet" cells forming a heavy and messy battery.

The French author E Hospitalier, in his "Domestic Electricity for Amateurs" of 1885, shows two motors for sewing machines in the home.

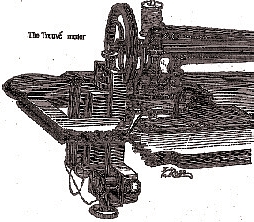

The first, Trouve's motor, is attached to a machine which I do not recognise. The motor has a vertical spindle with a rubber wheel which presses against the flywheel. The pressure is regulated by the spring shown.

The motor may be disconnected by moving a lever to move the pulley away from the flywheel. The author continues: "the band may then be replaced and the machine can be worked by the treadle, which is very convenient if the battery, by negligence or any other cause, may be exhausted."

Speed control was by a pedal which altered the tension in a chain of silver links. Changing the tension changed the resistance of the chain. Pedal operated variable resistances to control the speed of a motor have been with us for over a century.

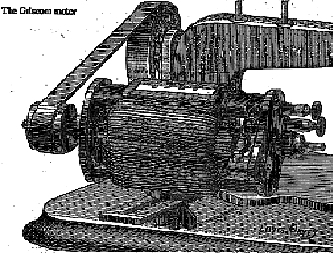

The second, the Griscom motor, is applied to a standard "New Family" machine. It was about the size of a modern bolt-on motor and produced 30W, a good figure for the time.

It was attached similarly; "a small slotted support and a wing-nut on the lower part of the motor are all that are required."

The motor was operated from a six-cell battery using zinc and carbon electrodes in potassium dichromate and sulphuric acid.

The speed of the motor was regulated by a pedal linked to the mechanism to wind the electrodes in and out of the liquid.

The battery weighed about 50kg (110 lb) and a single charge of zinc (about 700g) and chemicals was said to be sufficient for 500 to 1,000 metres of sewing.

Martin Gregory